Chitsulo chachitsulo chotuwazipolopolo nkhungu castingsndi ntchito zakutentha mankhwalandi mankhwala pamwamba.

Kujambula kwa zipolopolondondomeko amatchedwanso pre- TACHIMATA utomoni mchenga kuponya ndondomeko, otentha chipolopolo akamaumba castings kapena pachimake kuponyera ndondomeko. Zomwe zimapangidwira kwambiri ndi mchenga wa phenolic resin, womwe umakhala wokwera mtengo kuposa mchenga wobiriwira ndi furan resin. Kuphatikiza apo, mchengawu sungagwiritsidwenso ntchito.

Furan resin kudziumitsa mchenga kuponya (njira ya nobake) amagwiritsa ntchito furan resin yokutidwa mchenga kupanga nkhungu kuponyera. Pambuyo kusakaniza mchenga wapachiyambi (kapena mchenga wobwezeretsedwa), utomoni wamadzimadzi wa furan ndi chothandizira chamadzimadzi mofanana, ndikuwadzaza mu bokosi lapakati (kapena mchenga), ndiyeno mumangirire kuti likhale lolimba mu nkhungu kapena nkhungu mu bokosi lapakati (kapena mchenga). box) pa kutentha. Ndiye kuponya nkhungu kapena kuponyera pachimake anapangidwa, amene amatchedwa kudziletsa kuumitsa ozizira pachimake bokosi akamaumba (pachimake), kapena kudziletsa kuumitsa njira (pachimake).

Chifukwa nkhungu imapangidwa pa kutentha kwa chipinda ndipo palibe chifukwa chotenthetsa, kudzipangira mchenga wouma kumatchedwanso kuti palibe-bake casting process. Njira yodziumitsa yokha imatha kugawidwa mu acid-catalyzed furan resin ndi phenolic resin mchenga kudziletsa njira, urethane resin mchenga kudziletsa kuumitsa njira ndi phenolic monoester kudziletsa kuumitsa njira.

Monga mchenga wodziumitsa wowumitsa, mchenga wa furan resin ndiye mchenga wakale kwambiri komanso womwe amagwiritsidwa ntchito kwambiri pakupanga mchenga ku China. Kuchuluka kwa utomoni wowonjezeredwa mumchenga wowumba nthawi zambiri kumakhala 0.7% mpaka 1.0%, ndipo kuchuluka kwa utomoni wowonjezera mumchenga wapakati nthawi zambiri kumakhala 0.9% mpaka 1.1%. Zomwe zili mu aldehyde yaulere mu furan resin ndizochepera 0.3%, ndipo mafakitale ena atsikira pansi pa 0.1%. M'malo oyambira ku China, mchenga wowumitsa utomoni wa furan wafika pamlingo wapadziko lonse lapansi mosasamala kanthu za njira yopangira komanso mawonekedwe apamwamba a castings.

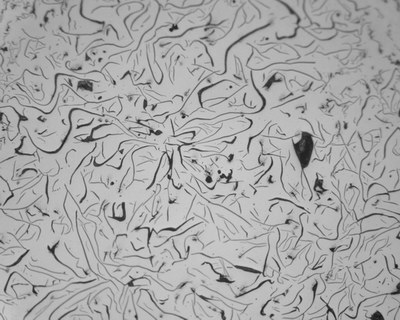

Iron imvi, kapena chitsulo chotuwira, ndi mtundu wachitsulo chopangidwa ndi graphite microstructure. Amatchulidwa ndi mtundu wa imvi wa fracture yomwe imapanga. Chitsulo cha imvi chimagwiritsidwa ntchito popanga nyumba zomwe kuuma kwa chigawocho kuli kofunika kwambiri kuposa mphamvu zake zowonongeka, monga zitsulo zamkati za injini zoyaka moto, nyumba zapampu, matupi a valve, mabokosi amagetsi, zolemera zowerengera ndi zokongoletsera zokongoletsera. Matenthedwe apamwamba a chitsulo cha Grey cast ndi mutu wake nthawi zambiri amagwiritsidwa ntchito popanga zophikira zachitsulo ndi ma disc brake rotor.

Zomwe zimapangidwira kuti mupeze graphic microstructure ndi 2.5 mpaka 4.0% carbon ndi 1 mpaka 3% silicon polemera. Graphite amatha kutenga 6 mpaka 10% ya voliyumu yachitsulo chotuwa. Silicon ndi yofunika kupanga chitsulo imvi mosiyana ndi chitsulo choyera, chifukwa silicon ndi graphite stabilizing element mu iron cast, kutanthauza kuti amathandiza alloy kupanga graphite m'malo carbides chitsulo; pa 3% silicon pafupifupi palibe mpweya umene umakhala ndi mankhwala osakaniza ndi chitsulo.

graphite amatenga mawonekedwe a mbali zitatu za flake. M'miyeso iwiri, ngati malo opukutidwa adzawonekera pansi pa maikulosikopu, ma graphite flakes amawoneka ngati mizere yabwino. Nsonga za flakes zimagwira ntchito ngati nsonga zakale; kotero, ndi brittle. Kukhalapo kwa ma graphite flakes kumapangitsa Grey Iron kuti ikhale yosavuta kupanga chifukwa imakonda kusweka mosavuta kudutsa ma graphite flakes. Chitsulo chotuwira chimakhalanso ndi mphamvu yabwino kwambiri yonyowetsa, chifukwa chake chimagwiritsidwa ntchito kwambiri ngati maziko oyika zida zamakina.

Katundu Wamakina a Grey Cast Iron | |||||||

| Zinthu molingana ndi DIN EN 1561 | Yesani | Chigawo | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | Chithunzi cha EN-JL 1030 | Chithunzi cha EN-JL1040 | Mtengo wa EN-JL 1050 | Chithunzi cha EN-JL1060 | |||

| Kulimba kwamakokedwe | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Mphamvu Zokolola | rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Mphamvu | A | % | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 |

| Compressive Mphamvu | σdB ndi | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Compressive Mphamvu | s0, 1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Mphamvu | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Ma modules a elasticity | E | GPA | 78-103 | 88-113 | 103-118 | 108-137 | 123-143 |

| Poisson nambala | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell kuuma | HB | 160-190 | 180-220 | 190-230 | 200-240 | 210-250 | |

| Ductility | σbw | MPa | 70 | 90 | 120 | 140 | 145 |

| Kupanikizika ndi kupanikizika kumasintha | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Kuphwanya Mphamvu | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Kuchulukana | g/cm3 | 7, 10 | 7, 15 | 7,20 | 7, 25 | 7,30 | |

Gulu Lofanana la Iron ya Gray Cast | ||||||||

| AISI | W-otsika | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 | GG-10 | Gulu la 100 | 0110-00 | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Gawo la 150 | 0115-00 | Pa 15 D | pa fg15 | FC 150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Gawo la 200 | 0120-00 | Pa 20 D | pa fg20 | FC200 | G20 pa |

| A48-40B | 0.6025 | GG-25 | Gawo la 250 | 0125-00 | Pa 25 D | pa fg25 | FC250 | pa g25 |

| A48-45B | 0.6030 | GG-30 | Gawo la 300 | 0130-00 | Pa 30 D | pa fg30 | FC 300 | ku g30 |

| A48-50B | 0.6035 | GG-35 | Gawo la 350 | 0135-00 | pa 35D | pa fg35 | Mtengo wa FC350 | pa g35 |

| A48-60B | 0.6040 | GG-40 | Gawo la 400 | 0140-00 | Pa 40 D | - | FC40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | Mtengo wa FCM330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | Mtengo wa MN450 | - | FCMP 440/490 | Chithunzi cha GMN45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | Mtengo wa FCMP490 | Chithunzi cha GMN55 |

| A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | Mtengo wa MN650-3 | - | Mtengo wa FCMP590 | Chithunzi cha GMN65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 pa | Mtengo wa MN 60-3 | - | Mtengo wa FCMP540 | - |

| A220-80002 | 0.8170 | GTS-70-02 | P690/2 | 0862-00 | Mtengo wa MN700-2 | - | Mtengo wa FCMP690 | Chithunzi cha GMN70 |

Utomoni Wokutidwa ndi Mchenga Woponyera Chitsulo ndi Aloyi | |

| Zitsulo & Aloyi | Gulu Lotchuka |

| Gray Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodular) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Chitsulo cha Carbon | C20, C25, C30, C45 |

| Aloyi Chitsulo | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Chitsulo chosapanga dzimbiri | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Mpweya Woumitsa Chitsulo chosapanga dzimbiri, Duplex Stainless Steel |

| Aluminiyamu Aloyi | ASTM A356, ASTM A413, ASTM A360 |

| Ma Aloyi a Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, ndi GB | |

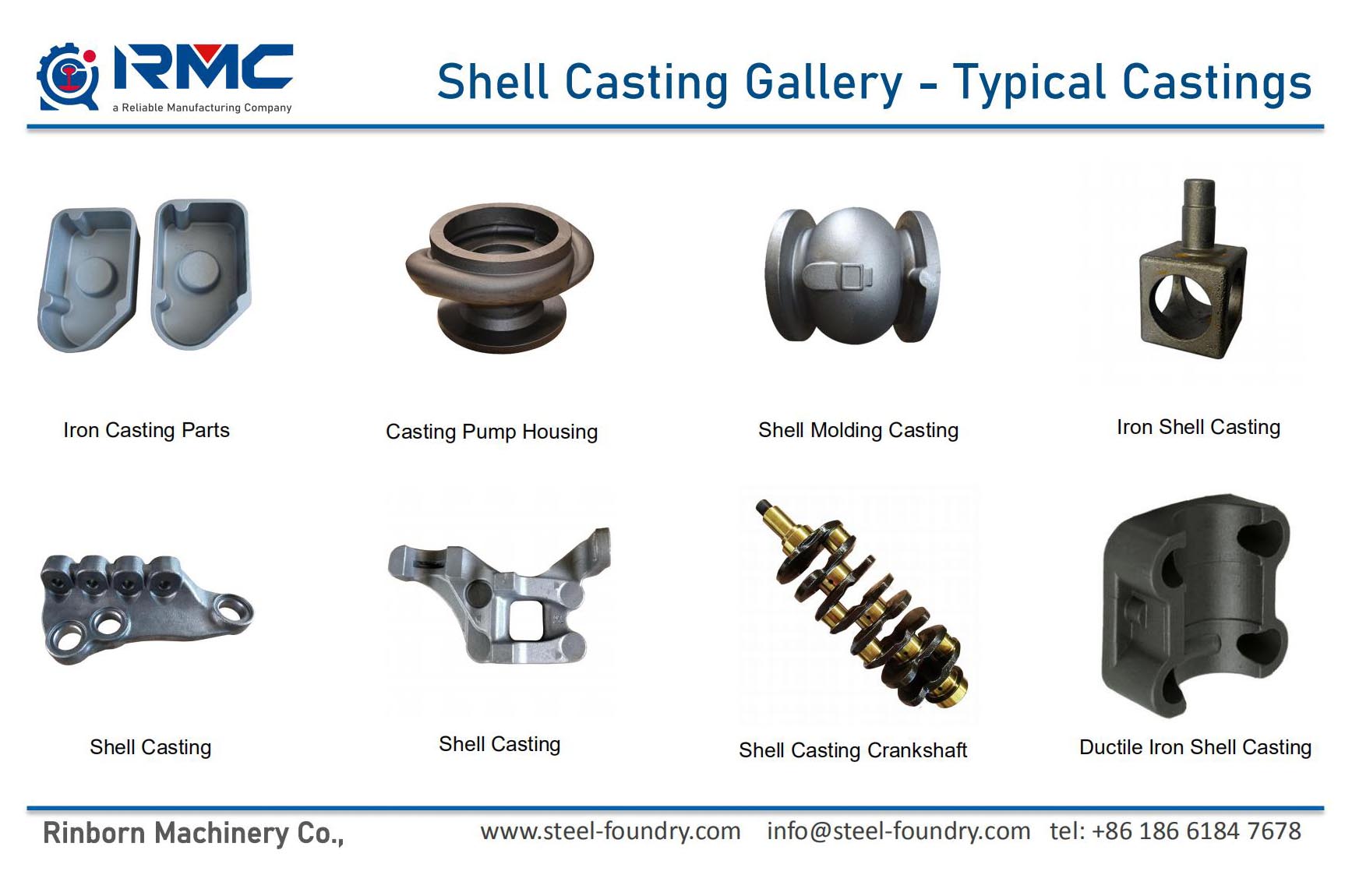

Zopangira Zopangira Iron Cast