Kutentha kwazitsulo zopangira zitsulo kumachokera pa chithunzi cha Fe-Fe3C kuti chiwongolere microstructure yazitsulo zazitsulo kuti zikwaniritse zofunikira. Chithandizo cha kutentha ndi chimodzi mwazinthu zofunika kwambiri popanga zitsulo zachitsulo. Ubwino ndi zotsatira za chithandizo cha kutentha zimagwirizana mwachindunji ndi ntchito yomaliza ya castings zitsulo.

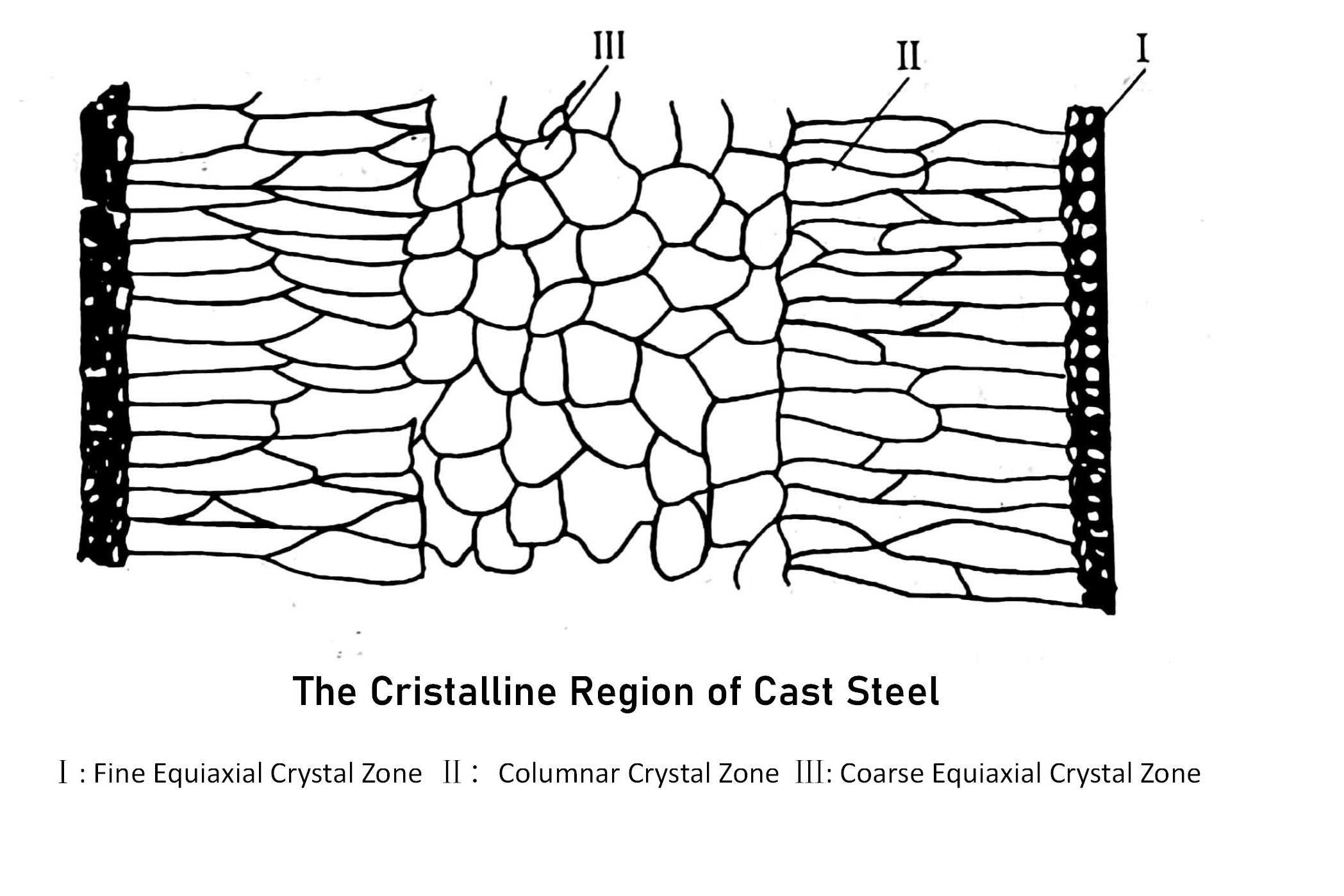

Mapangidwe a as-cast of castings zitsulo amadalira pakupanga mankhwala ndi kulimbitsa. Nthawi zambiri, pali kusiyana kwakukulu kwa dendrite, kapangidwe kosagwirizana kwambiri ndi njere zolimba. Chifukwa chake, ma castings azitsulo nthawi zambiri amafunika kutenthedwa kuti athetse kapena kuchepetsa zovuta zomwe zili pamwambapa, kuti apititse patsogolo luso lamakina azitsulo. Kuonjezera apo, chifukwa cha kusiyana kwa mapangidwe ndi makulidwe a khoma lazitsulo zazitsulo, mbali zosiyanasiyana za kuponyedwa komweko zimakhala ndi machitidwe osiyanasiyana a bungwe ndipo zimapanga kupsinjika kwakukulu kotsalira mkati. Choncho, ma castings zitsulo (makamaka alloy steel castings) ayenera kuperekedwa mumkhalidwe wotentha.

1. Makhalidwe a The Heat Treatment of Steel Castings

1) Mu mawonekedwe a as-cast of castings zitsulo, nthawi zambiri pamakhala coarse dendrites ndi tsankho. Panthawi yochizira kutentha, nthawi yotentha iyenera kukhala yokwera pang'ono kuposa ya zitsulo zopangira zida zomwezo. Pa nthawi yomweyi, nthawi yogwira ntchito ya austenitization iyenera kukulitsidwa moyenera.

2) Chifukwa cha kulekanitsa kwakukulu kwa mawonekedwe a as-cast of some alloy steel castings, kuti athetse chikoka chake pazomaliza za castings, miyeso iyenera kutengedwa kuti ipange homogenize panthawi ya chithandizo cha kutentha.

3) Pazitsulo zazitsulo zokhala ndi mawonekedwe ovuta komanso kusiyana kwakukulu kwa khoma, zotsatira zapakatikati ndi kuponyera kupanikizika ziyenera kuganiziridwa panthawi ya chithandizo cha kutentha.

4) Pamene chithandizo cha kutentha chikuchitidwa pazitsulo zazitsulo, ziyenera kukhala zomveka potengera mawonekedwe ake ndikuyesera kupewa mapindikidwe a castings.

2. Njira Yaikulu Zomwe Zimayambitsa Kutentha Kwachidziwitso cha Steel Castings

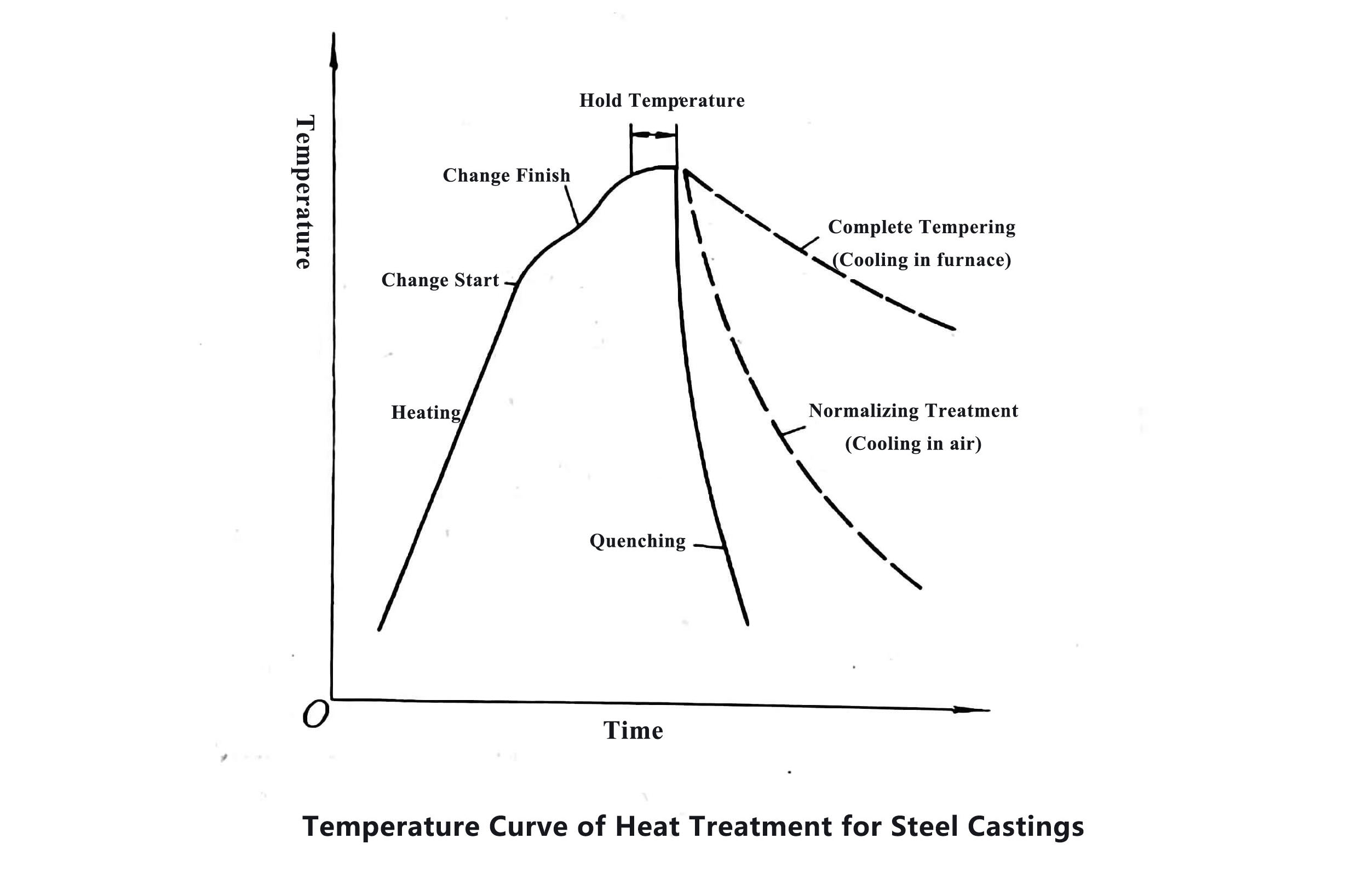

Kutentha kwazitsulo zazitsulo kumakhala ndi magawo atatu: kutentha, kusunga kutentha, ndi kuzizira. Kutsimikiza kwa magawo a ndondomeko kuyenera kukhazikitsidwa ndi cholinga chowonetsetsa kuti zinthu zili bwino komanso ndalama zopulumutsira.

1) Kutentha

Kuwotcha ndi njira yowonongeka kwambiri yogwiritsira ntchito kutentha kwa kutentha. Zigawo zazikulu zaukadaulo za njira yowotchera ndikusankha njira yoyenera yotenthetsera, liwiro la kutentha ndi njira yolipirira.

(1) Njira yotenthetsera. Njira zotenthetsera zopangira zitsulo zimaphatikizanso kutenthetsa kowala, kutenthetsa madzi amchere ndi kutentha kwa induction. Mfundo yosankhidwa ya njira yotenthetsera ndi yofulumira komanso yofanana, yosavuta kulamulira, yogwira ntchito kwambiri komanso yotsika mtengo. Mukatenthetsa, chopangiracho chimaganizira za kukula kwake, kapangidwe ka mankhwala, njira yochizira kutentha komanso zofunikira pakuponya.

(2) Liwiro la kutentha. Kwa zitsulo zambiri zoponyera zitsulo, kuthamanga kwa kutentha sikungakhale kochepa, ndipo mphamvu yaikulu ya ng'anjo imagwiritsidwa ntchito potentha. Kugwiritsa ntchito kutentha kwa ng'anjo yotentha kumatha kufupikitsa kwambiri nthawi yotentha komanso nthawi yopangira. Ndipotu, pansi pa kutentha kwachangu, palibe hysteresis yodziwika bwino ya kutentha pakati pa pamwamba pa kuponyera ndi pachimake. Kutentha kwapang'onopang'ono kumabweretsa kuchepa kwa magwiridwe antchito, kugwiritsa ntchito mphamvu zambiri, komanso makutidwe ndi okosijeni kwambiri ndi decarburization pamwamba pa kuponyera. Komabe, kwa ma castings ena okhala ndi mawonekedwe ovuta ndi mapangidwe, makulidwe akulu akulu, ndi kupsinjika kwakukulu kwamafuta panthawi yotentha, liwiro la kutentha liyenera kuwongoleredwa. Nthawi zambiri, kutentha pang'ono ndi kutentha pang'onopang'ono (pansi pa 600 ° C) kapena kukhala pa kutentha kochepa kapena kwapakati kungagwiritsidwe ntchito, ndiyeno kutentha kofulumira kungagwiritsidwe ntchito kumalo otentha kwambiri.

(3) Njira yotsegula. Mfundo yakuti zitsulo zoponyera zitsulo ziyenera kuikidwa mu ng'anjo ndikugwiritsira ntchito mokwanira malo ogwira ntchito, kuonetsetsa kutentha kwa yunifolomu ndikuyika ma castings kuti awonongeke.

2) Insulation

Kutentha kogwira kwa austenitization ya castings zitsulo ziyenera kusankhidwa molingana ndi mankhwala a chitsulo choponyedwa ndi zinthu zofunika. Kutentha kogwirizira kumakhala kokwera pang'ono (pafupifupi 20 °C) kuposa zitsulo zopangira zida zomwezo. Popanga zitsulo za eutectoid, ziyenera kutsimikiziridwa kuti ma carbides amatha kuphatikizidwa mwachangu mu austenite, komanso kuti austenite imatha kusunga mbewu zabwino.

Zinthu ziwiri ziyenera kuganiziridwa pa nthawi yosungira kutentha kwazitsulo zazitsulo: chinthu choyamba ndi kupanga kutentha kwa malo oponyera pamwamba ndi yunifolomu yapachiyambi, ndipo chinthu chachiwiri ndikuonetsetsa kuti mawonekedwewo akugwirizana. Choncho, nthawi yogwira makamaka imadalira kutentha kwa kutentha kwa kuponyera, makulidwe a khoma la gawo ndi zinthu za alloy. Nthawi zambiri, zopangira zitsulo za alloy zimafunikira nthawi yayitali kuposa zitsulo za kaboni. Kuchuluka kwa khoma la kuponyera nthawi zambiri kumakhala maziko akuluakulu owerengera nthawi yogwira. Pa nthawi yogwira chithandizo cha kutentha ndi kukalamba, zinthu monga cholinga cha chithandizo cha kutentha, kusunga kutentha ndi kufalikira kwa zinthu ziyenera kuganiziridwa.

3) Kuziziritsa

The castings zitsulo akhoza utakhazikika pa liwiro losiyana pambuyo kuteteza kutentha, kuti amalize kusintha metallographic, kupeza zofunika metallographic dongosolo ndi kukwaniritsa zizindikiro za ntchito. Nthawi zambiri, kuonjezera kuzizira kungathandize kupeza kamangidwe kabwino ndikuyeretsa njere, potero kumapangitsa kuti makinawo aziyenda bwino. Komabe, ngati kuzizira kumathamanga kwambiri, ndikosavuta kuyambitsa kupsinjika kwakukulu pakuponya. Izi zitha kuyambitsa mapindikidwe kapena kusweka kwa ma castings okhala ndi zovuta.

Malo ozizira opangira kutentha kwazitsulo nthawi zambiri amaphatikizapo mpweya, mafuta, madzi, madzi amchere ndi mchere wosungunuka.

3. Njira Yochizira Kutentha kwazitsulo zazitsulo

Malinga ndi njira zosiyanasiyana zotenthetsera, kusunga nthawi ndi kuziziritsa, njira zochizira kutentha kwazitsulo zopangira zitsulo makamaka zimaphatikizira annealing, normalizing, quenching, tempering, solution solution, precipitation hardness, chithandizo cha kupsinjika maganizo ndi chithandizo chochotsa haidrojeni.

1) Kusintha.

Annealing ndi kutenthetsa chitsulo chomwe kapangidwe kake kamapatuka ku gawo lolingana kupita ku kutentha kwina komwe kumakonzedweratu ndi ndondomekoyi, ndiyeno pang'onopang'ono kuziziritsa pambuyo posungira kutentha (nthawi zambiri kuzirala ndi ng'anjo kapena kukwiriridwa ndi laimu) kuti mupeze njira yochizira kutentha pafupi ndi mgwirizano mkhalidwe wa kapangidwe. Malinga ndi kapangidwe ka chitsulo ndi cholinga ndi zofunika za annealing, annealing akhoza kugawidwa mu annealing wathunthu, isothermal annealing, spheroidizing annealing, recrystallization annealing, kupsinjika maganizo annealing ndi zina zotero.

(1) Kukonzekera kwathunthu. Njira yonse yopangira annealing wathunthu ndi: Kutenthetsa chitsulo choponyera mpaka 20 °C-30 °C pamwamba pa Ac3, ndikuchigwira kwa nthawi yayitali, kotero kuti kapangidwe kachitsulo kamasintha kukhala austenite, kenako kuzirala pang'onopang'ono (nthawi zambiri). kuziziritsa ndi ng'anjo) pa 500 ℃- 600 ℃, ndipo potsiriza utakhazikika pansi mu mlengalenga. Zomwe zimatchedwa zonse zimatanthauza kuti dongosolo lathunthu la austenite limapezeka likatenthedwa.

Cholinga cha annealing annealing makamaka chimaphatikizapo: choyamba ndikuwongolera mawonekedwe owoneka bwino komanso osagwirizana chifukwa cha ntchito yotentha; chachiwiri ndi kuchepetsa kuuma kwa carbon zitsulo ndi aloyi zitsulo castings pamwamba sing'anga mpweya, potero kuwongolera ntchito yawo kudula (ambiri, Pamene kuuma workpiece pakati 170 HBW-230 HBW, n'zosavuta kudula. ndizokwera kapena zotsika kuposa izi, zimapangitsa kudula kukhala kovuta); chachitatu ndikuchotsa kupsinjika kwamkati kwachitsulo choponyera chitsulo.

Kugwiritsidwa ntchito kwa annealing kwathunthu. Annealing annealing makamaka oyenera zitsulo carbon ndi aloyi zitsulo castings ndi hypoeutectoid zikuchokera ndi mpweya zili kuyambira 0.25% mpaka 0.77%. Chitsulo cha hypereutectoid sichiyenera kutsekedwa kwathunthu, chifukwa chitsulo cha hypereutectoid chikatenthedwa pamwamba pa Accm ndikukhazikika pang'onopang'ono, simenti yachiwiri idzadutsa malire a tirigu wa austenite mu mawonekedwe a netiweki, zomwe zimapangitsa mphamvu, pulasitiki ndi kulimba kwachitsulo kukhala kofunikira. kuchepa.

(2) Isothermal Annealing. Isothermal annealing imatanthawuza kutenthetsa zitsulo mpaka 20 °C - 30 °C pamwamba pa Ac3 (kapena Ac1), mutatha kugwira kwakanthawi, kuzirala mwachangu mpaka kutentha kwapamwamba kwambiri kwa subcooled austenite isothermal curve, kenako ndikusunga kwakanthawi. nthawi (Pearlite transformation zone). Austenite ikasinthidwa kukhala pearlite, imazizira pang'onopang'ono.

(3) Spheroidizing Annealing. Spheroidizing annealing ndi kutenthetsa zitsulo zachitsulo kutentha kwapamwamba pang'ono kuposa Ac1, ndiyeno patatha nthawi yayitali yosungira kutentha, simenti yachiwiri muzitsulo imasandulika kukhala simenti ya granular (kapena yozungulira), ndiyeno pang'onopang'ono Kutentha kutentha. ndondomeko kuziziritsa kwa firiji.

Cholinga cha spheroidizing annealing chimaphatikizapo: kuchepetsa kuuma; kupanga mawonekedwe a metallographic yunifolomu; kukonza magwiridwe antchito ndikukonzekera kuzimitsa.

Spheroidizing annealing imagwira ntchito makamaka pazitsulo za eutectoid ndi zitsulo za hypereutectoid (zokhala ndi mpweya woposa 0.77%) monga chitsulo cha carbon tool, alloy spring steel, rolling bearing bear and alloy tool steel.

(4) Kuchepetsa kupsinjika kwapang'onopang'ono ndikuwonjezeranso kukonzanso. Kuchepetsa kupsinjika kumatchedwanso kuchepetsa kutentha. Ndi njira yomwe zitsulo zoponyera zitsulo zimatenthedwa mpaka kutentha kwa Ac1 (400 ° C - 500 ° C), kenako kusungidwa kwa nthawi ndithu, kenako kuzizizira pang'onopang'ono mpaka kutentha. Cholinga cha kuchepetsa nkhawa annealing ndi kuthetsa kupsinjika kwa mkati mwa kuponyera. Kapangidwe kazitsulo kachitsulo sikungasinthe panthawi yochepetsera nkhawa. Recrystallization annealing imagwiritsidwa ntchito makamaka kuthetsa mawonekedwe osokonekera omwe amayamba chifukwa cha kuzizira kozizira ndikuchotsa kuumitsa ntchito. Kutentha kwa kutentha kwa recrystallization annealing ndi 150 ° C - 250 ° C pamwamba pa kutentha kwa recrystallization. Recrystallization annealing imatha kupanganso njere za kristalo zotalikirana kukhala makhiristo ofananirako pambuyo pa kuzizira kozizira, potero kuthetsa kuuma kwa ntchito.

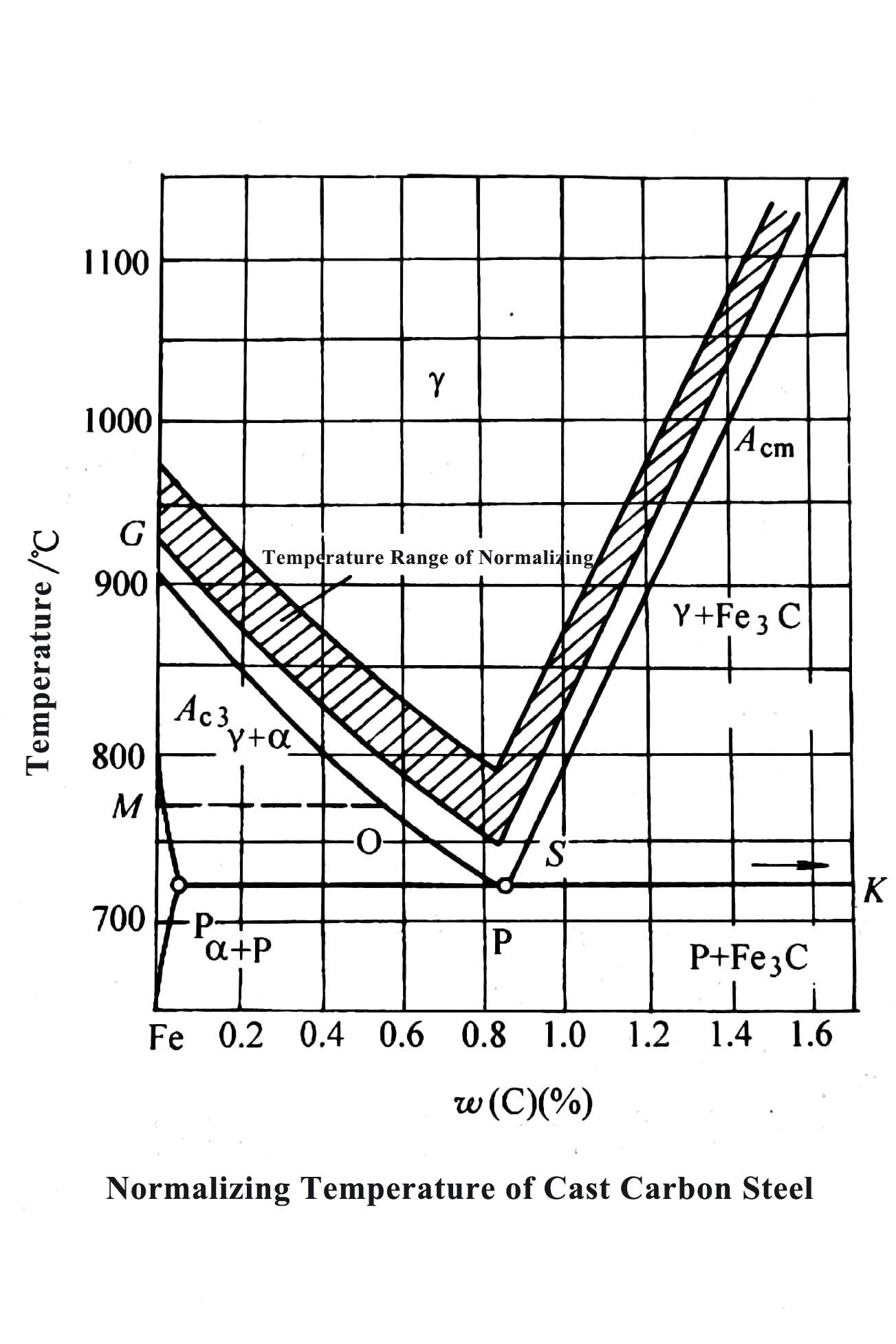

2) Normalizing

Normalizing ndi chithandizo cha kutentha chomwe chitsulo chimatenthedwa mpaka 30 ° C - 50 ° C pamwamba pa Ac3 (hypoeutectoid steel) ndi Acm (hypereutectoid steel), ndipo pakatha nthawi yosungira kutentha, imakhazikika mpaka kutentha mumlengalenga kapena mkati. mpweya wokakamiza. njira. Normalizing imakhala ndi kuzizira kofulumira kuposa kutsekera, kotero kuti kapangidwe kake kamakhala kocheperako kuposa kapangidwe ka anneal, ndipo mphamvu yake ndi kulimba kwake ndizokweranso kuposa zomwe zimapangidwira. Chifukwa chafupikitsa kupanga ndi kugwiritsira ntchito zida zapamwamba, normalizing imagwiritsidwa ntchito kwambiri popanga zitsulo zosiyanasiyana.

Cholinga cha normalizing chagawidwa m'magulu atatu awa:

(1) Normalizing monga chomaliza kutentha mankhwala

Kwa castings zitsulo ndi otsika mphamvu zofunika, normalizing angagwiritsidwe ntchito ngati chomaliza kutentha mankhwala. Normalizing akhoza kuyeretsa mbewu, homogenize dongosolo, kuchepetsa ferrite zili mu hypoeutectoid zitsulo, kuonjezera ndi kuyeretsa okhutira pearlite, potero kuwongolera mphamvu, kuuma ndi kulimba kwa chitsulo.

(2) Normalizing monga chithandizo chisanadze kutentha

Pakuti castings zitsulo ndi zigawo zikuluzikulu, normalizing pamaso quenching kapena quenching ndi tempering (kuzimitsa ndi kutentha kutentha tempering) akhoza kuthetsa Widmanstatten dongosolo ndi banded dongosolo, ndi kupeza bwino ndi yunifolomu dongosolo. Pakuti maukonde cementite alipo mu carbon steels ndi aloyi chida zitsulo ndi zinthu mpweya woposa 0,77%, normalizing akhoza kuchepetsa zili cementite yachiwiri ndi kupewa kupanga maukonde mosalekeza, kukonzekera bungwe spheroidizing annealing .

(3) Kupititsa patsogolo ntchito yodula

Normalizing akhoza kusintha ntchito kudula otsika mpweya zitsulo. Kulimba kwazitsulo zotsika za carbon zitsulo kumakhala kochepa kwambiri pambuyo pa annealing, ndipo n'zosavuta kumamatira ku mpeni panthawi yodula, zomwe zimapangitsa kuti pamwamba pakhale roughness. Kudzera normalizing kutentha mankhwala, kuuma otsika mpweya zitsulo castings akhoza ziwonjezeke kwa 140 HBW - 190 HBW, amene ali pafupi ndi mulingo woyenera kwambiri kudula kuuma, potero kuwongolera ntchito kudula.

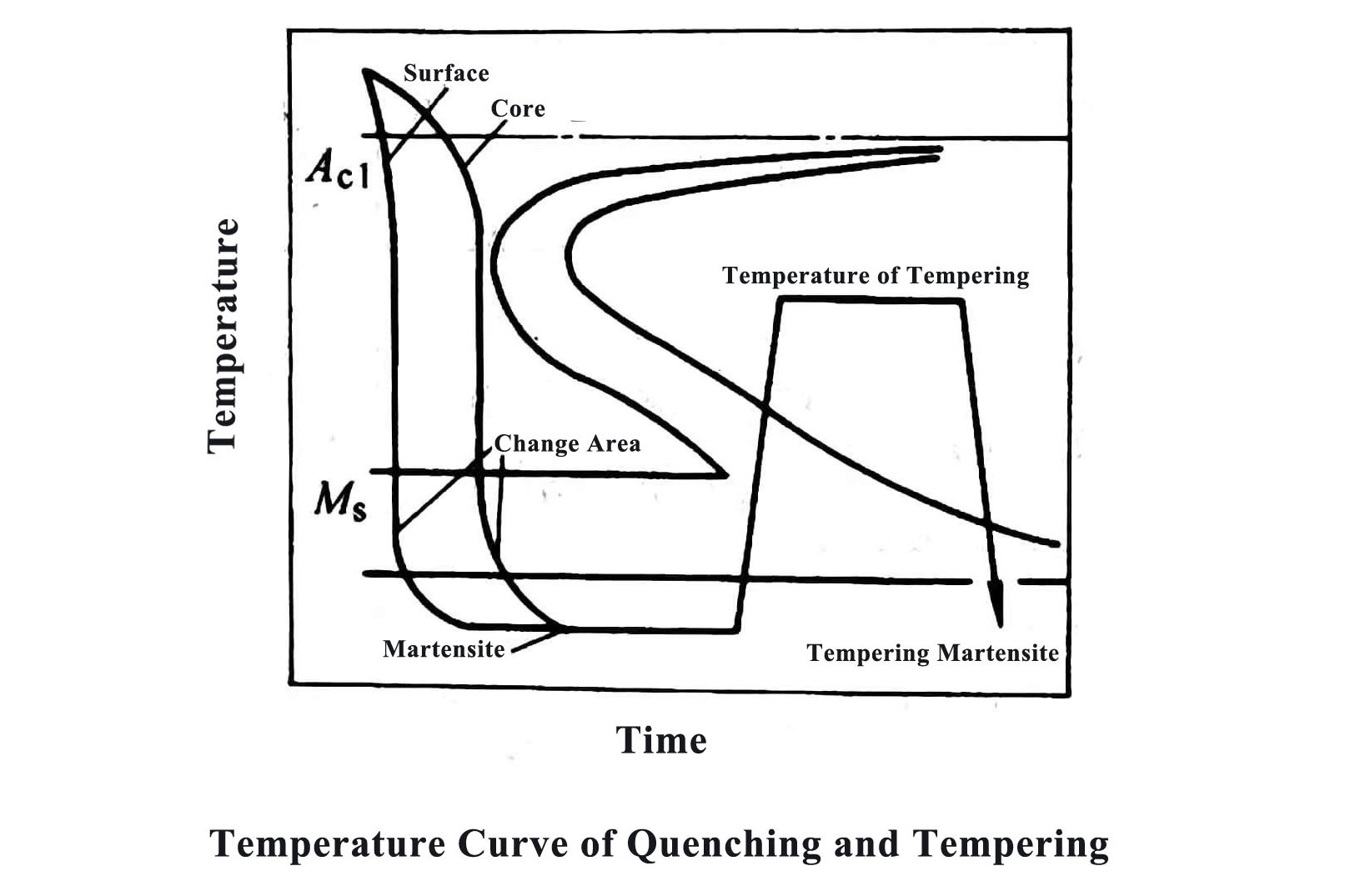

3) Kuchepetsa

Kuzimitsa ndi njira yochizira kutentha komwe zitsulo zoponyera zitsulo zimatenthedwa kutentha pamwamba pa Ac3 kapena Ac1, ndiyeno zimakhazikika mofulumira pambuyo pogwira kwa nthawi kuti mupeze dongosolo lonse la martensitic. The castings zitsulo ayenera kutenthedwa mu nthawi pambuyo otentha kwambiri kuthetsa nkhawa quenching ndi kupeza chofunika mabuku mawotchi katundu.

(1) Kuzimitsa kutentha

Kutentha kozimitsa kutentha kwachitsulo cha hypoeutectoid ndi 30 ℃-50 ℃ pamwamba pa Ac3; Kutentha kozimitsa kwachitsulo cha eutectoid ndi chitsulo cha hypereutectoid ndi 30 ℃-50 ℃ pamwamba pa Ac1. Hypoeutectoid carbon steel imatenthedwa ndi kutentha kozimitsa komwe tatchula pamwambapa kuti tipeze austenite yabwino, ndipo mawonekedwe abwino a martensite atha kupezeka pambuyo pozimitsa. Chitsulo cha eutectoid ndi chitsulo cha hypereutectoid chakhala spheroidized ndikumangirizidwa kuzimitsidwa ndi kutentha kusanachitike, chifukwa chake mutatha kutentha mpaka 30 ℃-50 ℃ pamwamba pa Ac1 ndikutsimikiziridwa mosakwanira, mawonekedwewo ndi austenite komanso osasungunuka pang'ono kulowa mkati mwa tinthu tating'ono ta Carbon. Pambuyo kuzimitsa, austenite imasandulika kukhala martensite, ndipo tinthu tating'ono ta cementite timasungidwa. Chifukwa cha kuuma kwakukulu kwa simenti, sikungochepetsa kuuma kwachitsulo, komanso kumapangitsanso kukana kwake kuvala. Mapangidwe abwinobwino achitsulo cha hypereutectoid ndi abwino flaky martensite, ndi simenti yabwino granular ndi kachulukidwe kakang'ono ka austenite wosungidwa amagawidwa mofanana pa matrix. Kapangidwe kameneka kali ndi mphamvu zambiri komanso kukana kuvala, komanso kumakhala ndi mphamvu zina.

(2) Kuzirala sing'anga kuzimitsa kutentha kutentha ndondomeko

Cholinga cha kuzimitsa ndikupeza martensite wathunthu. Choncho, kuzizira kwa chitsulo choponyedwa panthawi yozimitsa kuyenera kukhala kwakukulu kuposa kuzizira kozizira kwambiri kwa chitsulo choponyedwa, apo ayi mawonekedwe a martensite ndi katundu wofanana sangathe kupezeka. Komabe, kuzizira kwambiri kungayambitse kupotoza kapena kusweka kwa kuponyera. Kuti mukwaniritse zofunikira zomwe zili pamwambazi panthawi imodzimodziyo, malo ozizirira oyenera ayenera kusankhidwa malinga ndi zomwe akuponyera, kapena njira yoziziritsira pasiteji iyenera kutsatiridwa. Pakutentha kwa 650 ℃-400 ℃, kusinthasintha kwa isothermal kwa supercooled austenite yachitsulo ndikokula kwambiri. Choncho, pamene kuponyera kuzimitsidwa, kuziziritsa mofulumira kuyenera kutsimikiziridwa mu kutentha uku. Pansi pa Ms point, kuziziritsa kuyenera kukhala kocheperako kuti tipewe kuwonongeka kapena kusweka. Sing'anga yozimitsa nthawi zambiri imatenga madzi, njira yamadzimadzi kapena mafuta. Pagawo lozimitsa kapena kutsitsa, zoulutsira zomwe zimagwiritsidwa ntchito nthawi zambiri zimaphatikizapo mafuta otentha, chitsulo chosungunuka, mchere wosungunuka kapena alkali wosungunuka.

Kutha kuzirala kwa madzi m'malo otentha kwambiri a 650 ℃-550 ℃ ndi amphamvu, ndipo kuziziritsa kwamadzi m'dera lotsika la 300 ℃-200 ℃ ndikolimba kwambiri. Madzi ndi abwino kwambiri kuzimitsa ndi kuziziritsa za carbon zitsulo castings ndi akalumikidzidwa osavuta ndi lalikulu mtanda zigawo. Akagwiritsidwa ntchito pozimitsa ndi kuziziritsa, kutentha kwa madzi nthawi zambiri sikudutsa 30 ° C. Choncho, kaŵirikaŵiri amavomerezedwa kulimbitsa kayendedwe ka madzi kuti kutentha kwa madzi kukhale koyenera. Kuonjezera apo, kutentha mchere (NaCl) kapena alkali (NaOH) m'madzi kudzawonjezera kwambiri kuzizira kwa yankho.

Ubwino waukulu wa mafuta ngati sing'anga kuzirala ndi kuti mlingo kuzirala mu otsika kutentha zone 300 ℃-200 ℃ ndi otsika kwambiri kuposa madzi, amene angachepetse kwambiri nkhawa mkati mwa workpiece kuzimitsidwa ndi kuchepetsa kuthekera mapindikidwe. ndi kuwonongeka kwa khungu. Panthawi imodzimodziyo, mphamvu yoziziritsa ya mafuta mu kutentha kwakukulu kwa 650 ℃-550 ℃ ndi yotsika, yomwenso ndi vuto lalikulu la mafuta ngati sing'anga yozimitsa. Kutentha kwa mafuta ozizimitsa nthawi zambiri kumayendetsedwa pa 60 ℃-80 ℃. Mafuta amagwiritsidwa ntchito makamaka kuzimitsira zitsulo za aloyi zokhala ndi mawonekedwe ovuta komanso kuzimitsa zitsulo za carbon zitsulo ndi magawo ang'onoang'ono a mtanda ndi mawonekedwe ovuta.

Kuphatikiza apo, mchere wosungunuka umagwiritsidwanso ntchito ngati sing'anga yozimitsa, yomwe imakhala malo osambira amchere panthawiyi. Kusamba kwa mchere kumakhala ndi malo otentha kwambiri ndipo mphamvu yake yoziziritsa imakhala pakati pa madzi ndi mafuta. Kusamba mchere nthawi zambiri ntchito austempering ndi siteji quenching, komanso zochizira castings ndi akalumikidzidwa zovuta, miyeso yaing'ono ndi okhwima mapindikidwe zofunika.

4) Kuthamanga

Kutentha kumatanthawuza njira yochizira kutentha yomwe zitsulo zozimitsidwa kapena zowonongeka zimatenthedwa ndi kutentha komwe kumasankhidwa kutsika kusiyana ndi mfundo yovuta ya Ac1, ndipo itatha kugwira kwa nthawi, imakhazikika pamlingo woyenera. Kutentha kwa kutentha kumatha kusintha mawonekedwe osakhazikika omwe amapezeka pambuyo pozimitsa kapena kukhazikika kukhala chokhazikika kuti athetse kupsinjika ndikuwongolera pulasitiki ndi kulimba kwazitsulo zachitsulo. Nthawi zambiri, njira yochizira kutentha yozimitsa komanso kutentha kwambiri kumatchedwa quenching and tempering treatment. Zitsulo zozimitsidwa ziyenera kutenthedwa pakapita nthawi, ndipo zitsulo zokhazikika ziyenera kutenthedwa ngati pakufunika. Kuchita kwa castings zitsulo pambuyo kutentha kumadalira kutentha kwa kutentha, nthawi ndi nthawi zambiri. Kuwonjezeka kwa kutentha kwa kutentha ndi kuwonjezereka kwa nthawi yogwira nthawi iliyonse sikungathe kuthetseratu kupsinjika kwazitsulo zazitsulo, komanso kusintha kosasunthika kuzimitsidwa kwa martensite kukhala martensite, troostite kapena sorbite. Mphamvu ndi kuuma kwazitsulo zazitsulo zimachepetsedwa, ndipo pulasitiki imakhala bwino kwambiri. Kwa zitsulo zina zapakatikati zokhala ndi aloyi zomwe zimapanga ma carbides (monga chromium, molybdenum, vanadium ndi tungsten, etc.), kuuma kumawonjezeka ndipo kulimba kumachepa pakutentha pa 400 ℃-500 ℃. Chodabwitsa ichi chimatchedwa kuuma kwachiwiri, ndiko kuti, kuuma kwa zitsulo zotayidwa mumtundu waukali kumafika pamtunda. Pakupanga kwenikweni, zitsulo zapakatikati zotayira zokhala ndi mawonekedwe owumitsa achiwiri ziyenera kutenthedwa nthawi zambiri.

(1) Kutentha kochepa

Kutentha kosiyanasiyana kwa kutentha kwapakati ndi 150 ℃-250 ℃. Kutentha kwapang'onopang'ono kumatha kupeza mawonekedwe a martensite, omwe amagwiritsidwa ntchito kwambiri kuzimitsa zitsulo zambiri za carbon ndi kuzimitsa chitsulo cha aloyi. Tempered martensite amatanthauza kapangidwe ka cryptocrystalline martensite kuphatikiza ma carbides abwino a granular. Mapangidwe achitsulo cha hypoeutectoid pambuyo pa kutentha kwapansi kutentha ndi martensite; Kapangidwe ka chitsulo cha hypereutectoid pambuyo pa kutentha kwapang'onopang'ono kumatenthedwa ndi martensite + carbides + osungidwa austenite. Cholinga cha kutentha kwapang'onopang'ono ndikuwongolera moyenerera kulimba kwachitsulo chozimitsidwa ndikusunga kuuma kwakukulu (58HRC-64HRC), kulimba kwambiri komanso kukana kuvala, pomwe kumachepetsa kwambiri kupsinjika ndi kuphulika kwazitsulo zachitsulo.

(2) Kutentha kwapakati

Kutentha kwapakati pa kutentha kwapakati nthawi zambiri kumakhala pakati pa 350 ℃ -500 ℃. Kapangidwe pambuyo tempering pa sing'anga kutentha ndi kuchuluka kwa zabwino-grained cementite omwazika ndi anagawira pa masanjidwewo ferrite, ndiko kuti, mtima troostite dongosolo. The ferrite mu tempered troostite structure akadali ndi mawonekedwe a martensite. Kupsyinjika kwamkati kwazitsulo zazitsulo pambuyo pa kutentha kumathetsedwa, ndipo ali ndi malire apamwamba komanso zokolola, mphamvu zapamwamba ndi kuuma, komanso pulasitiki yabwino komanso kulimba.

(3) Kutentha kwambiri

Kutentha kwakukulu kwa kutentha kumakhala 500 ° C-650 ° C, ndipo njira yochizira kutentha yomwe imaphatikiza kuzimitsa ndi kutentha kotsatira kutentha kumatchedwa chithandizo cha quenching ndi kutentha. Kapangidwe pambuyo pa kutentha kwambiri kutentha ndi tempered sorbite, ndiko kuti, fine-grained cementite ndi ferrite. The ferrite mu tempered sorbite ndi polygonal ferrite yomwe imalowanso recrystallization. Kuponyedwa kwachitsulo pambuyo pa kutentha kwakukulu kumakhala ndi machitidwe abwino amakina okhudzana ndi mphamvu, pulasitiki ndi kulimba. Kutentha kwakukulu kumagwiritsidwa ntchito kwambiri muzitsulo zamkati za carbon, chitsulo chochepa cha alloy, ndi magawo osiyanasiyana ofunikira omwe ali ndi mphamvu zovuta.

5) Solid SolutionTtreatment

Cholinga chachikulu cha chithandizo chamankhwala ndikusungunula ma carbides kapena magawo ena amvula munjira yolimba kuti apeze mawonekedwe opitilira gawo limodzi. Kuponyedwa kwachitsulo chosapanga dzimbiri cha austenitic, chitsulo cha austenitic manganese ndi mpweya wowumitsa zitsulo zosapanga dzimbiri ziyenera kukhala zolimba. Kusankhidwa kwa kutentha kwa yankho kumadalira kapangidwe ka mankhwala ndi chithunzi cha gawo la chitsulo choponyedwa. Kutentha kwa austenitic manganese zitsulo castings zambiri 1000 ℃ - 1100 ℃; kutentha kwa austenitic chromium-nickel zosapanga dzimbiri castings zitsulo zambiri 1000 ℃-1250 ℃.

Kukwera kwa kaboni muzitsulo zotayidwa komanso zinthu zosasungunuka zomwe sizingasungunuke, kutentha kwake kuyenera kukhala kolimba. Kuti mvula iwumitse zitsulo zokhala ndi mkuwa, kulimba kwa zitsulo zoponyera zitsulo kumawonjezeka chifukwa cha mvula ya magawo olimba a mkuwa pa nthawi yozizirira. Pofuna kufewetsa kapangidwe kake ndikuwongolera magwiridwe antchito, ma castings azitsulo amayenera kukhala olimba. Kutentha kwake kolimba ndi 900 ℃-950 ℃.

6) Chithandizo Choumitsa Mvula

Mpweya kuumitsa chithandizo ndi kubalalitsidwa kulimbikitsa mankhwala ikuchitika mkati tempering kutentha osiyanasiyana, amatchedwanso kukalamba yokumba. Chofunika kwambiri cha mankhwala owumitsa mvula ndikuti pa kutentha kwakukulu, ma carbides, nitrides, intermetallic compounds ndi magawo ena osakhazikika apakati amawombedwa kuchokera ku njira yolimba ya supersaturated ndikubalalika mu masanjidwewo, motero kumapangitsa kuti chitsulocho chikhale chokwanira.

Kutentha kwa mankhwala okalamba kumakhudza mwachindunji ntchito yomaliza ya castings zitsulo. Ngati kutentha kwa ukalamba kuli kochepa kwambiri, gawo lowumitsa mvula lidzayamba pang'onopang'ono; ngati kutentha kwa ukalamba kuli kokwera kwambiri, kudzikundikira kwa gawo lokhazikika kumayambitsa kuchulukirachulukira, ndipo kuchita bwino kwambiri sikungapezeke. Choncho, mazikowo ayenera kusankha kutentha koyenera kwa ukalamba malinga ndi kalasi yachitsulo choponyedwa ndi ntchito yodziwika ya kuponyedwa kwachitsulo. Kutentha kokalamba kwa chitsulo cha austenitic chosagwira kutentha kumakhala 550 ℃-850 ℃; kutentha kwaukalamba kwamphamvu kwambiri mpweya wowumitsa zitsulo nthawi zambiri ndi 500 ℃.

7) Chithandizo cha Kupsinjika Maganizo

Cholinga cha chithandizo cha kutentha kwa nkhawa ndikuchotsa kupsinjika, kuthetsa kupsinjika ndi kupsinjika komwe kumapangidwa ndi makina, kuti akhazikitse kukula kwa kuponyera. Chithandizo cha kutentha kwa nkhawa nthawi zambiri chimatenthedwa mpaka 100 ° C-200 ° C pansi pa Ac1, kenako chimasungidwa kwakanthawi, ndipo pamapeto pake chimakhazikika ndi ng'anjo. Mapangidwe a zitsulo zachitsulo sizinasinthe panthawi yachisokonezo. Zopangira zitsulo za kaboni, zopangira zitsulo zotsika kwambiri komanso zitsulo zokhala ndi aloyi wapamwamba kwambiri zitha kuthandizidwa ndi chithandizo chothandizira kupsinjika.

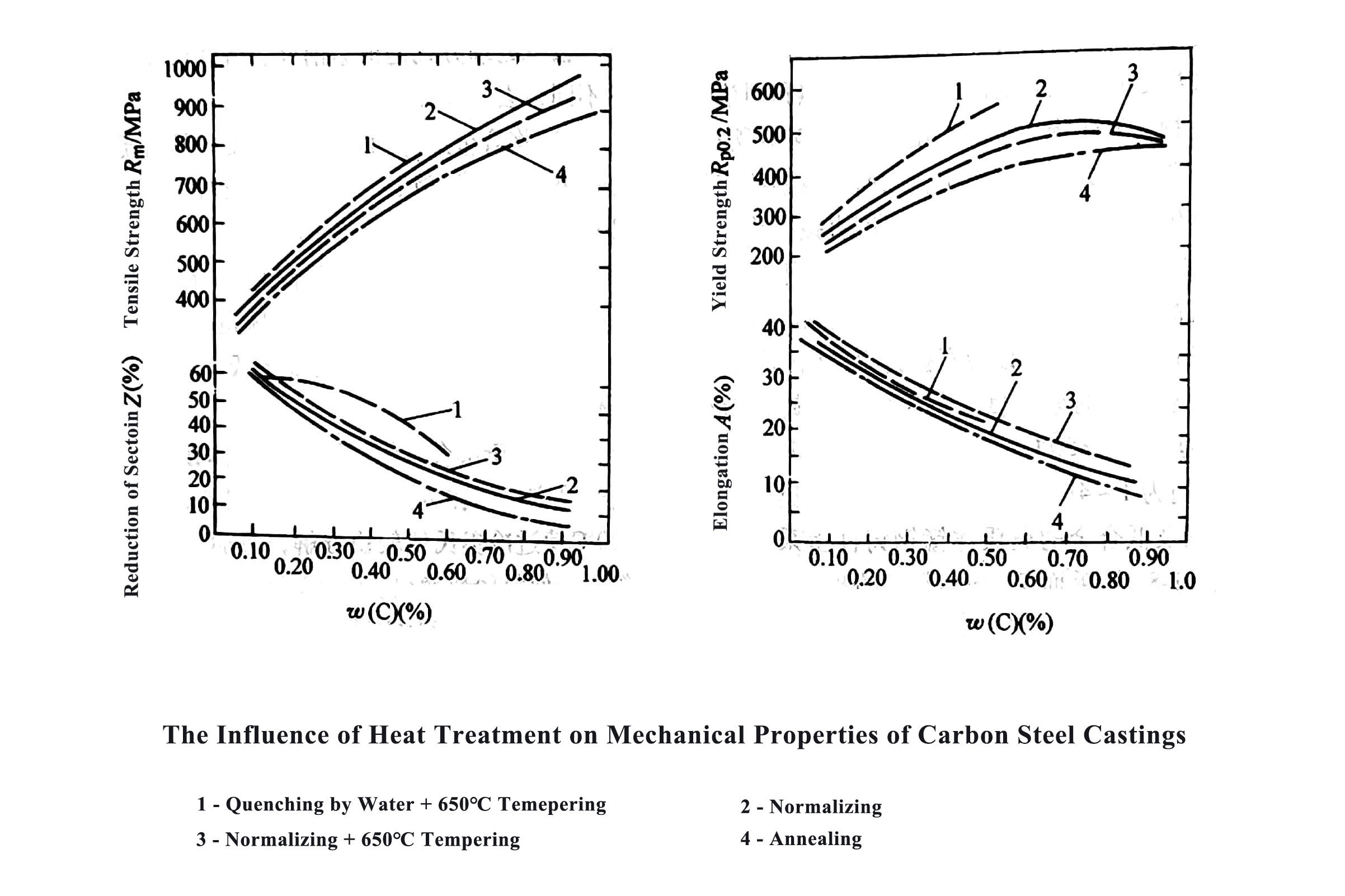

4. Zotsatira za Chithandizo cha Kutentha pa Zida za Steel Castings

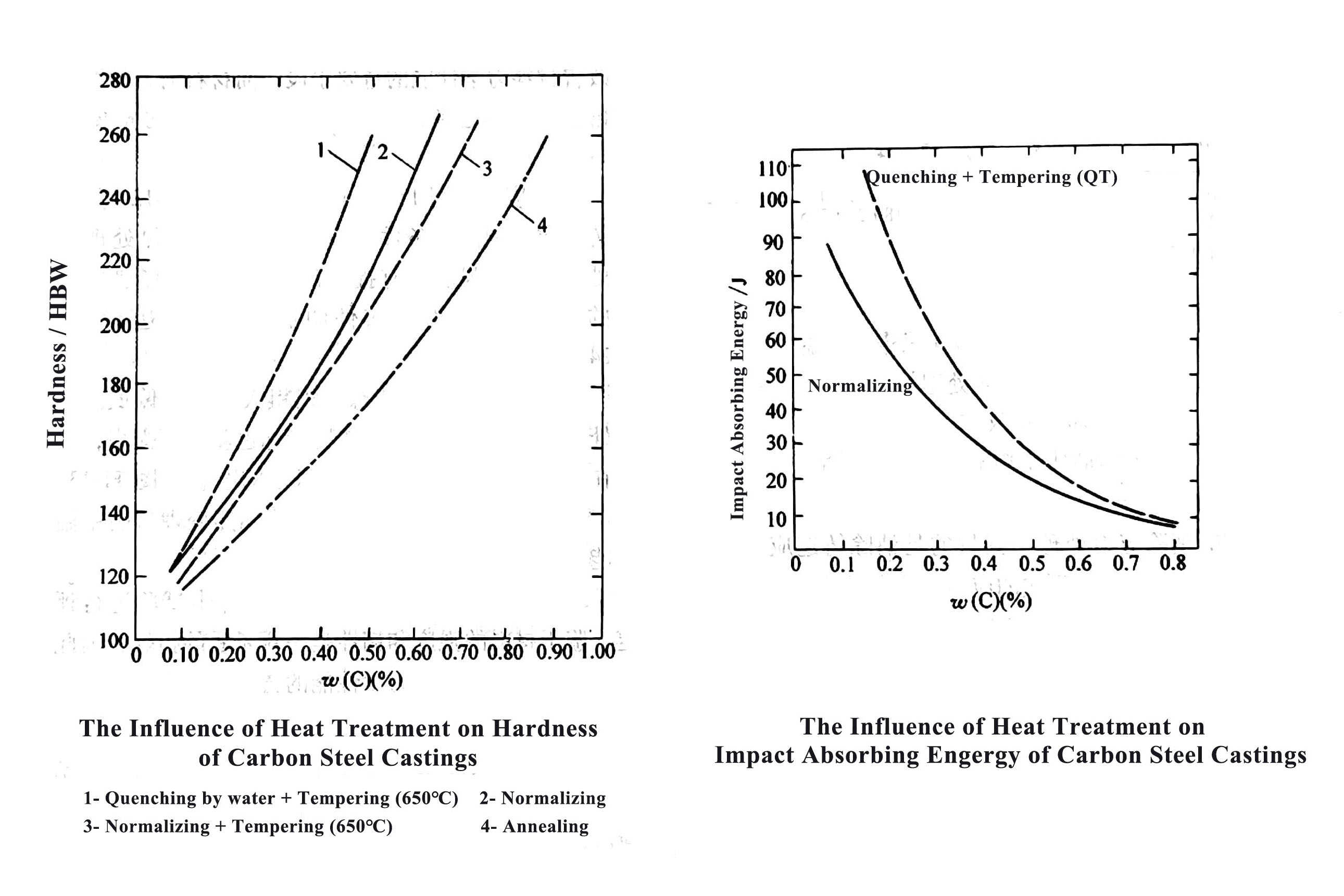

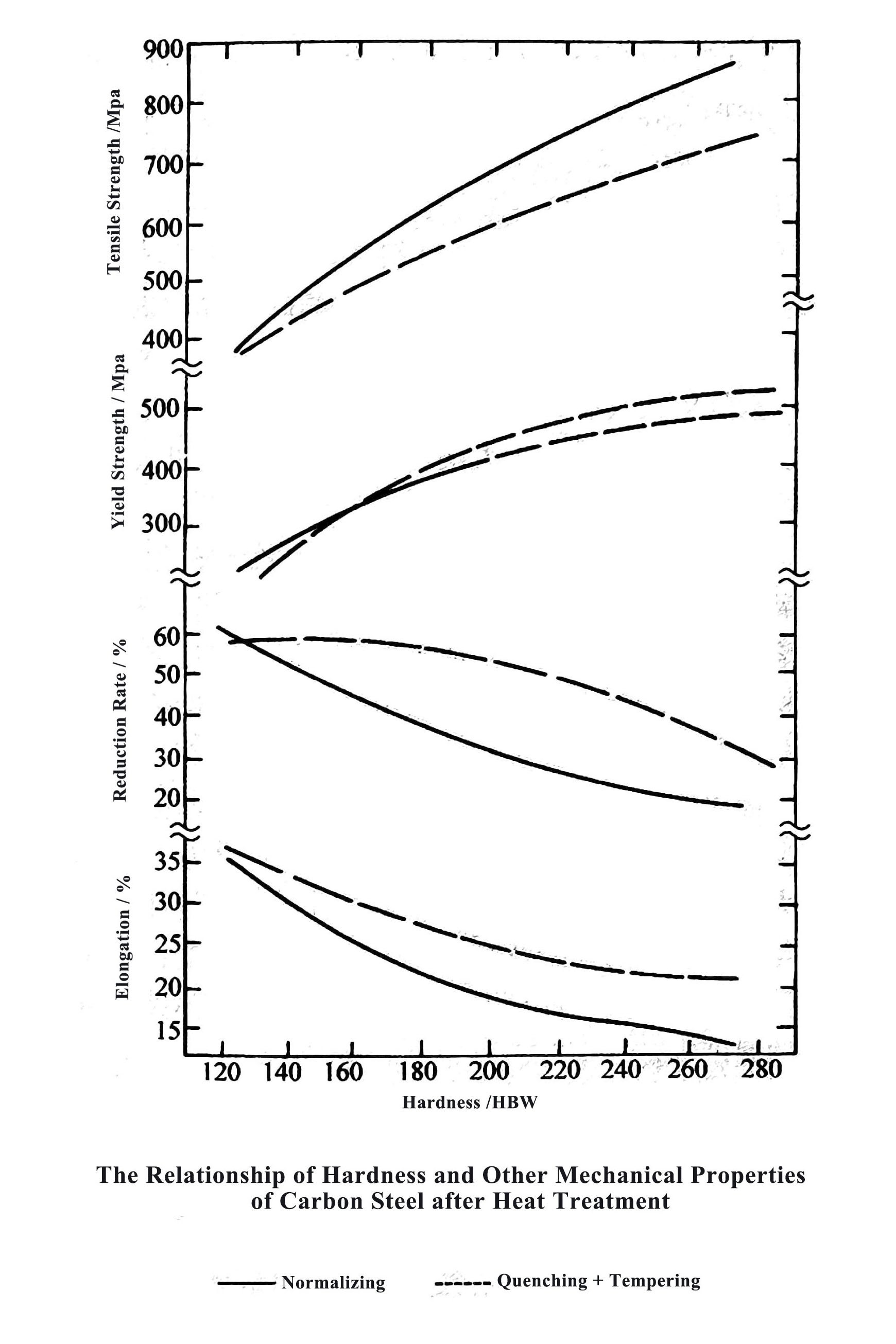

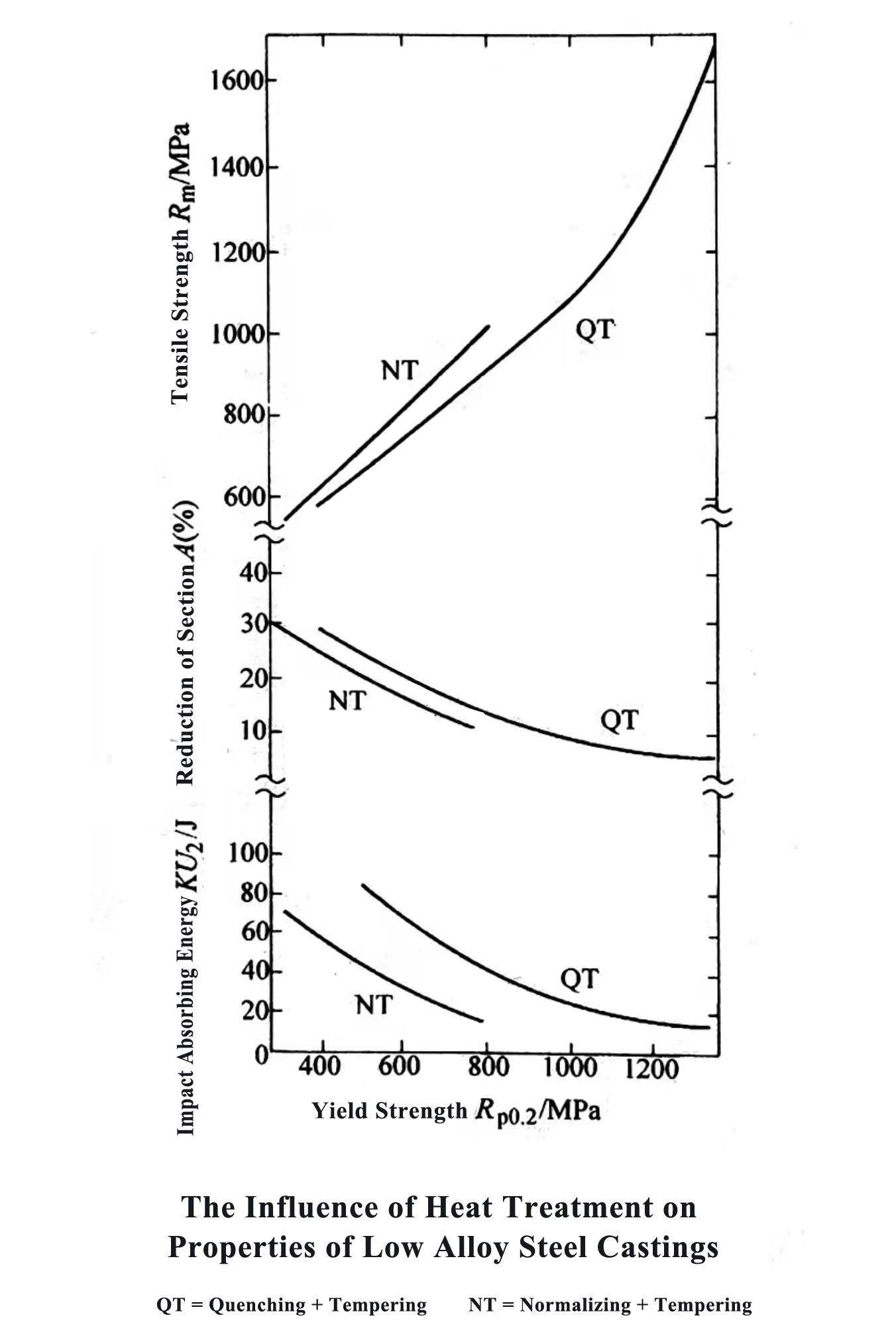

Kuphatikiza pa magwiridwe antchito achitsulo kutengera kapangidwe kake ndi njira yoponyera, njira zosiyanasiyana zochizira kutentha zitha kugwiritsidwanso ntchito kuti zikhale ndi zida zabwino kwambiri zamakina. Cholinga chachikulu cha njira yochizira kutentha ndikuwongolera mtundu wa castings, kuchepetsa kulemera kwa ma castings, kuwonjezera moyo wautumiki ndikuchepetsa ndalama. Kutentha mankhwala ndi njira yofunika kusintha mawotchi zimatha castings; The makina katundu castings ndi chizindikiro chofunika kuweruza zotsatira za kutentha kutentha. Kuphatikiza pa zinthu zotsatirazi, mazikowo ayenera kuganiziranso zinthu monga njira zopangira, kudula magwiridwe antchito komanso zofunikira zogwiritsira ntchito popanga zitsulo zopangira kutentha.

1) Chikoka cha Chithandizo cha Kutentha pa Mphamvu ya Castings

Pansi pa chikhalidwe cha zitsulo zomwezo, mphamvu yazitsulo zopangira zitsulo pambuyo pa njira zosiyanasiyana zochizira kutentha zimakhala ndi chizolowezi chowonjezeka. Nthawi zambiri, mphamvu zamakokedwe za castings carbon zitsulo ndi otsika aloyi castings zitsulo akhoza kufika 414 Mpa-1724 MPa pambuyo kutentha mankhwala.

2) Zotsatira za Chithandizo cha Kutentha pa Plasticity ya Steel Castings

Mapangidwe a as-cast of castings zitsulo ndi ovuta ndipo pulasitiki ndi yotsika. Pambuyo pa chithandizo cha kutentha, microstructure yake ndi pulasitiki zidzakonzedwa bwino. Makamaka plasticity ya castings zitsulo pambuyo kuzimitsa ndi kutentha mankhwala (kuzimitsa + kutentha kutentha tempering) adzakhala kwambiri bwino.

3) Kulimba kwa Zitsulo Castings

The toughness index of zitsulo castings nthawi zambiri amawunikidwa ndi kuyesa zotsatira. Popeza mphamvu ndi kulimba kwa castings zitsulo ndi zizindikiro zotsutsana, maziko ayenera kuganizira mozama kuti asankhe njira yoyenera yochizira kutentha kuti akwaniritse zinthu zonse zamakina zomwe makasitomala amafuna.

4) Zotsatira za Chithandizo cha Kutentha Pakuuma kwa Castings

Pamene kuuma kwa zitsulo zotayidwa mofanana, kuuma kwa chitsulo choponyedwa pambuyo pa chithandizo cha kutentha kumatha kusonyeza mphamvu ya chitsulo choponyedwa. Chifukwa chake, kuuma kungagwiritsidwe ntchito ngati cholozera chowoneka bwino kuti muyerekeze ntchito yachitsulo choponyedwa pambuyo pa chithandizo cha kutentha. Nthawi zambiri, kuuma kwa carbon steel castings kumatha kufika 120 HBW - 280 HBW pambuyo pa chithandizo cha kutentha.

Nthawi yotumiza: Jul-12-2021