Ku RMC Casting Foundry, timatengerautomoni TACHIMATA mchenga nkhungu(palibe kuphika ndi kudzilimbitsa) kuponya mkuwa, mkuwa ndi ma aloyi ena amkuwa.

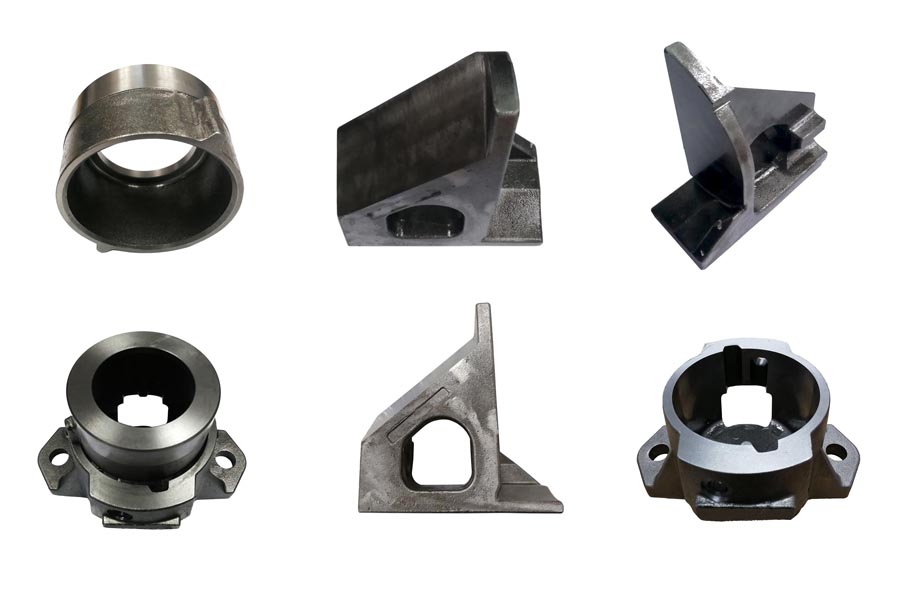

Zojambula zamkuwaamagwiritsidwa ntchito kwambiri mu ma valve ndi pampu chifukwa cha ntchito yabwino ya zipangizo zamkuwa. Ku RMC Foundry, timapanga makamakazitsulo zamkuwandi kuponya mchenga wobiriwira, utomoni wokutira mchenga,kuponya ndalamandi zoponya zazikulu zamkuwa, timatengeranso njira yotayira thovu ndi vacuum. Nthawi zambiri, ma castings amkuwa opangidwa ndi kuponya mchenga ndiye gulu lalikulu muzoyambira zathu.

Aloyi yamkuwa yokhala ndi zinki monga chinthu chachikulu cholumikizira nthawi zambiri chimatchedwa mkuwa. Copper-zinki binary alloy amatchedwa wamba mkuwa, ndipo ternary, quaternary kapena multielement mkuwa wopangidwa ndi kuwonjezera pang'ono zinthu zina pamaziko a aloyi yamkuwa-zinki amatchedwa mkuwa wapadera. Cast brass amagwiritsidwa ntchito kupanga mkuwa popanga castings. Kuponyedwa kwa mkuwa kumagwiritsidwa ntchito kwambiri popanga makina, ma valve ndi mapampu, zombo, ndege, magalimoto, zomangamanga ndi mafakitale ena, okhala ndi zolemera zina zazitsulo zolemera zopanda chitsulo, kupanga mndandanda wazitsulo zamkuwa.

Poyerekeza ndi mkuwa ndi mkuwa, kusungunuka kolimba kwa zinki mumkuwa ndi kwakukulu kwambiri. Pansi pa kutentha kwanthawi zonse, pafupifupi 37% ya zinc imatha kusungunuka mkuwa, ndipo pafupifupi 30% ya zinc imatha kusungunuka m'malo otayira, pomwe malata amkuwa Mumkhalidwe wa as-cast, gawo lalikulu la kusungunuka kolimba kwa malata. mumkuwa ndi 5% mpaka 6%. Gawo lalikulu la kusungunuka kolimba kwa aluminiyumu mkuwa wamkuwa ndi 7% mpaka 8%. Chifukwa chake, zinc imakhala ndi njira yabwino yolimbikitsira mkuwa. Panthawi imodzimodziyo, zinthu zambiri zowonjezera zimatha kusungunuka mkuwa ku madigiri osiyanasiyana , Komanso kupititsa patsogolo makina ake, kotero kuti mkuwa, makamaka mkuwa wapadera uli ndi makhalidwe amphamvu kwambiri. Mtengo wa zinki ndi wotsika kuposa wa aluminiyamu, mkuwa, ndi malata, ndipo uli ndi zinthu zambiri. Kuchuluka kwa zinki komwe kumawonjezeredwa ku mkuwa ndikokulirapo, motero mtengo wamkuwa ndi wotsika kuposa mkuwa wa malata ndi mkuwa wa aluminiyamu. Brass ili ndi kutentha pang'ono kolimba, madzi abwino, komanso kusungunula kosavuta.

Chifukwa mkuwa uli ndi makhalidwe omwe tawatchulawa amphamvu kwambiri, mtengo wotsika komanso ntchito yabwino yoponyera, mkuwa uli ndi mitundu yambiri, zotulutsa zazikulu komanso ntchito zambiri kuposa mkuwa wa malata ndi mkuwa wa aluminiyamu muzitsulo zamkuwa. Komabe, kukana kuvala ndi kukana kwa mkuwa sikuli bwino ngati mkuwa, makamaka kukana kwa dzimbiri ndi kukana kwa mkuwa wamba ndizochepa. Pokhapokha pamene zinthu zina za alloy ziwonjezeredwa kuti zipange mkuwa wapadera wapadera, kukana kwake kuvala ndi kukana kwa dzimbiri kwasinthidwa ndikuwongolera.

Monga mchenga wodziumitsa wokha, mchenga wosaphika wa furan umagwiritsidwa ntchito kwambiri popanga mchenga wachitsulo wotuwa komanso njira zopangira chitsulo. Pamwamba pa nkhungu yamchenga ikanalimba kuti ikhale yovuta pambuyo poyaka moto. Chifukwa chake, njira yoponyera mchenga wa furan itha kugwiritsidwa ntchito kupanga magawo apakati komanso akulu akulu, kuyambira ma kilogalamu khumi mpaka matani matani. Ndi mawonekedwe abwino a pamwamba, kulolerana kolimba komanso zolakwika zochepa zoponyera, njira zoponyera mchenga wa furan zitha kugwiritsidwa ntchito kupanga zida zovuta zoponya.

RMC imagwiritsa ntchito njira yosaphika mchenga popanga zitsulo zosapanga dzimbiri, zitsulo zosapanga dzimbiri, zitsulo zachitsulo, ndi chitsulo chotuwira. Mu ndondomeko ya No-Bake, nkhungu za mchenga zimapangidwa ndi matabwa kapena zitsulo. Mchenga wa tirigu wabwino umaphatikizidwa ndi chomangira cha utomoni mu chosakaniza chamchenga chothamanga kwambiri ndikugwetsa mubokosi lomwe lili ndi chitsanzocho. Mphindi zochepa pambuyo pake, chisakanizo cha mchenga-binder chimadzilimbitsa ndipo nkhungu imachotsedwa pamapangidwe. Mitambo ya Mchenga popanga mkati mwa mapangidwe a castings amapangidwa pogwiritsa ntchito njira yomweyo nthawi yomweyo. Pambuyo pazitsulo ndi nkhungu zakunja zimasonkhanitsidwa, zimatsekedwa ndikukonzekera kutsanulira zitsulo. Zida zina, monga ma ductile iron castings, zimafunikira chisamaliro chapadera chachitsulo chisanayambe kuthira. Njira yopangira No-Bake imakhala yosinthika kwambiri chifukwa imalola kuti zitsulo zachitsulo ndi zitsulo zisungidwe kuti zikhale zolekerera bwino komanso zimatha kuthana ndi kukula kwa magawo makumi a magalamu mpaka matani makumi.

Masitepe Opanda Njira Yopangira Zipolopolo:

No bake ndi njira yoponyera yomwe imaphatikizapo kugwiritsa ntchito zomangira za mankhwala kuti amangirire mchenga wowumba. Mchenga umaperekedwa kumalo odzaza nkhungu pokonzekera kudzaza nkhungu. Chosakaniza chimagwiritsidwa ntchito kusakaniza mchenga ndi mankhwala binder ndi chothandizira. Mchenga ukatuluka mu chosakanizira, chomangiracho chimayamba kuuma. Njira iyi yodzaza nkhungu ingagwiritsidwe ntchito pa theka lililonse la nkhungu (kuthana ndi kukoka). Theka lililonse la nkhungu limapangidwa kuti likhale lolimba komanso lowundana. Kenako, rollover imagwiritsidwa ntchito kuchotsa theka la nkhungu mu bokosi lachitsanzo. Mchenga utatha, mutha kuchapa nkhungu. Miyendo, ngati ikufunika, imayikidwa mu kukoka ndipo kupirira kumatsekedwa pazitsulo kuti amalize nkhungu. Magalimoto angapo onyamula nkhungu ndi ma conveyor amasuntha nkhunguyo kuti itsike. Akathira, nkhungu imaloledwa kuziziritsa isanagwedezeke. Kugwedeza kumaphatikizapo kuthyola mchenga wowumbidwa kutali ndi kuponyera. Kenako kuponya kumapita kumalo omaliza kuti achotse chokwera, kuponya komaliza ndi kumaliza. Mchenga wophwanyika umaphwanyidwanso mpaka mchengawo ubwererenso kukula kwake. Mchengawu ukhoza kutengedwanso kuti ukaugwiritsenso ntchito poponya kapena kuchotsedwa kuti ukatayidwe. Kuwotchanso kwa matenthedwe ndiyo njira yabwino kwambiri, yokwanira yosawotchera mchenga.

| Zida Zopangira Shell Mold Casting ku RMC Foundry | |

| Zitsulo & Aloyi | Gulu Lotchuka |

| Gray Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Chitsulo cha Carbon | C20, C25, C30, C45 |

| Aloyi Chitsulo | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Chitsulo chosapanga dzimbiri | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Mpweya Woumitsa Chitsulo chosapanga dzimbiri, Duplex Stainless Steel |

| Aluminiyamu Aloyi | ASTM A356, ASTM A413, ASTM A360 |

| Ma Aloyi a Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, ndi GB | |