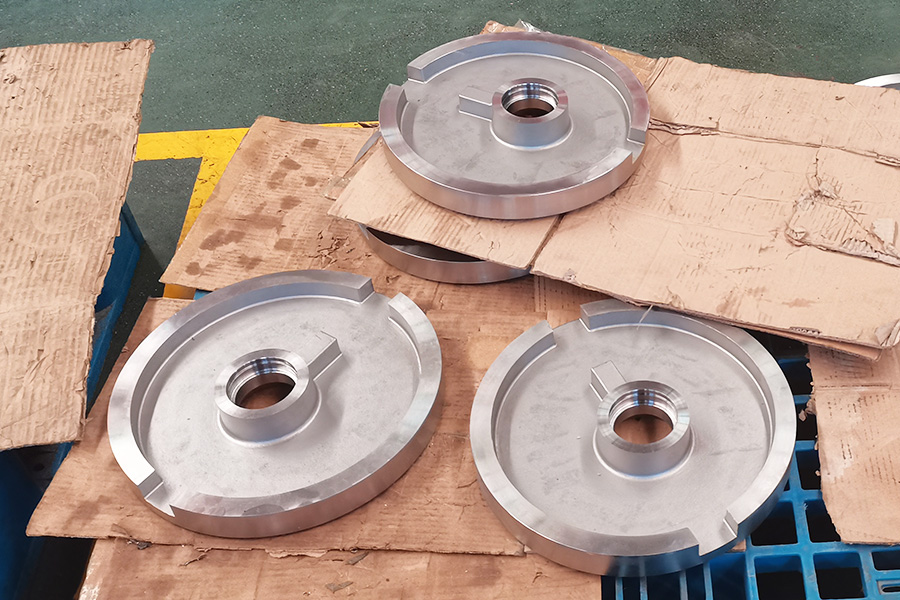

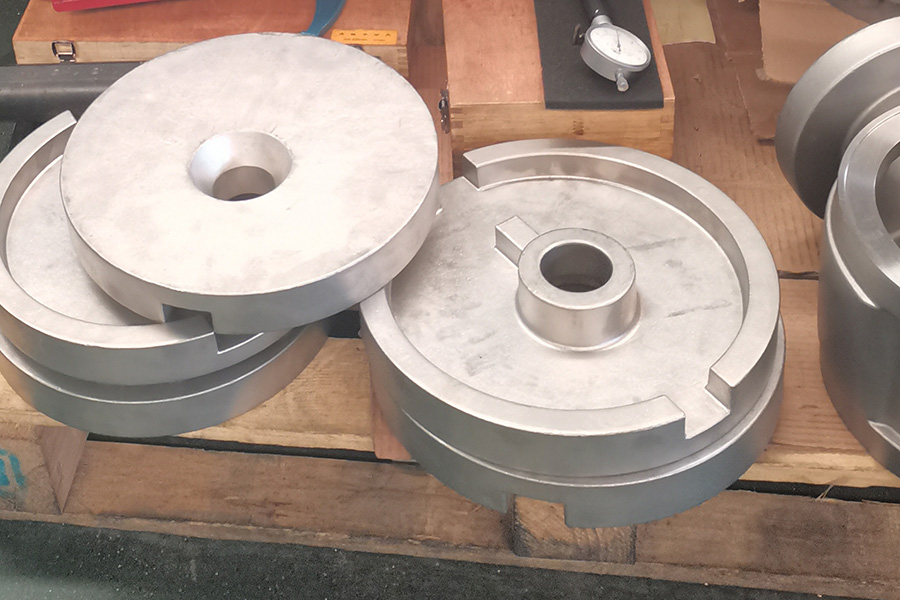

Cobalt based alloy investments casting products from China original foundry with heat treatment and CNC Machining services

| Zitsulo zaInvestment Casting Njiraku RMC | |||

| Gulu | China Grade | US Grade | Germany Grade |

| Chitsulo cha Carbon | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Chitsulo cha Low Alloy | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 3, 2, 1.713, 2. 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Chida Chitsulo | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Chitsulo Chosagwira Kutentha | 20Cr25Ni20, 16Cr23Ni13, Mtengo wa 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Cobalt-base Alloy | UMC50, 670, Giredi 31 | 2.4778 | |

Cobalt-based alloy ndi alloy yolimba yomwe imatha kupirira mitundu yosiyanasiyana ya kuvala, dzimbiri komanso kutentha kwambiri kwa okosijeni. Cobalt-based alloys amachokera ku cobalt monga gawo lalikulu, lomwe lili ndi faife wochuluka, alloying chemical elements monga chromium, tungsten ndi kachigawo kakang'ono ka alloying monga molybdenum, niobium, tantalum, titaniyamu, lanthanum, ndipo nthawi zina chitsulo. . Malinga ndi kapangidwe kake ka aloyi, aloyi yochokera ku cobalt imatha kupangidwa kukhala waya wowotcherera, ndipo ufa ukhoza kugwiritsidwa ntchito ngati kuwotcherera pamwamba, kupopera mbewu mankhwalawa, kuwotcherera utsi ndi njira zina, komanso kutha kupangidwanso. , forgings ndi zitsulo za ufa. Odziwika ndi kugwiritsidwa ntchito komaliza, ma aloyi opangidwa ndi cobalt amatha kugawidwa kukhala ma alloys osamva kuvala a cobalt, ma aloyi otenthetsera kwambiri a cobalt ndi ma alloys osagwirizana ndi dzimbiri. M'malo ogwirira ntchito, onse samva kuvala komanso kutentha kwambiri kapena kuvala komanso kusachita dzimbiri. Zina zogwirira ntchito zingafunikenso kutentha kwambiri, kuvala komanso kukana dzimbiri nthawi imodzi. Zomwe zimakhala zovuta kwambiri kuntchito, ndizodziwikiratu ubwino wa cobalt-based alloys.

Katundu wa Cobalt-Based Alloys

Ma carbides omwe ali mu cobalt-based superalloys ndi MC, M23C6 ndi M6C. Mu ma aloyi opangidwa ndi cobalt, M23C6 imalowetsedwa pakati pa malire ambewu ndi ma dendrites pakuzizira pang'onopang'ono. Mu ma aloyi ena, M23C6 yabwino imatha kupanga eutectic ndi matrix γ. MC carbide particles ndi zazikulu kwambiri kuti mwachindunji zimakhudza kwambiri dislocations, kotero kulimbikitsa zotsatira aloyi si zoonekeratu, pamene finely omwazika carbides ndi zabwino kulimbikitsa kwenikweni. Ma carbides omwe ali pamalire a tirigu (makamaka M23C6) amatha kuletsa kutsetsereka kwa malire a tirigu, potero kumapangitsa mphamvu yopirira. The microstructure ya cobalt-based superalloy HA-31 (X-40) ndi gawo lolimbikitsa lomwazika (CoCrW) 6 C-mtundu wa carbide. Magawo otsekeka a topological omwe amawonekera mu ma aloyi ena opangidwa ndi cobalt, monga sigma gawo ndi owopsa ndipo amapangitsa kuti alloy brittle.

Kukhazikika kwamafuta a carbides mu ma aloyi opangidwa ndi cobalt ndikwabwino. Kutentha kukakwera, kukula kwa carbide kukuwonjezeka pang'onopang'ono kusiyana ndi kukula kwa gawo la γ mu alloy-based alloy, ndipo kutentha kwa kusungunukanso mu matrix kumakweranso (mpaka 1100 ° C) . Choncho, kutentha kukakwera, cobalt-based alloy Mphamvu ya alloy nthawi zambiri imachepa pang'onopang'ono. Ma alloys opangidwa ndi cobalt ali ndi kukana bwino kwa dzimbiri. Chifukwa chomwe ma aloyi opangidwa ndi cobalt ndi apamwamba kuposa ma aloyi opangidwa ndi faifi pankhaniyi ndikuti malo osungunuka a cobalt sulfide (monga Co-Co4S3 eutectic, 877 ℃) ndi apamwamba kuposa a faifi tambala ( Mwachitsanzo, Ni-Ni3S2 eutectic (645°C) ndi okwera kwambiri, ndipo kuchuluka kwa sulfure mu cobalt ndikotsika kwambiri Ndipo chifukwa ma aloyi ambiri okhala ndi cobalt amakhala ndi ma chromium apamwamba kuposa ma aloyi opangidwa ndi nickel, amatha kupanga gawo loteteza la alkali metal sulfate (monga Cr2O3 wosanjikiza wotetezedwa ndi Na2SO4) pamwamba pa aloyi , kukana kwa okosijeni kwa ma aloyi opangidwa ndi cobalt nthawi zambiri kumakhala kotsika kwambiri kuposa komwe kumapangidwa ndi faifi tambala.

Mosiyana ndi ma superalloys ena, ma superalloys opangidwa ndi cobalt samalimbikitsidwa ndi gawo lolamula lamvula lomwe limalumikizidwa mwamphamvu ndi matrix, koma amapangidwa ndi matrix a austenite fcc omwe ali yankho lolimba lolimbikitsidwa komanso ma carbides ochepa omwe amagawidwa mu matrix. Ma superalloys opangidwa ndi cobalt amadalira kwambiri kulimbikitsa kwa carbide. Makristalo oyera a cobalt ali ndi mawonekedwe a kristalo a hexagonal (hcp) pansi pa 417 ° C, omwe amasintha kukhala fcc pa kutentha kwambiri. Pofuna kupewa kusinthika kumeneku pakugwiritsa ntchito ma superalloys opangidwa ndi cobalt, pafupifupi ma aloyi onse opangidwa ndi cobalt amathiridwa ndi faifi tambala kuti akhazikitse kapangidwe kake kuchokera kuchipinda chozizira kupita ku kutentha kosungunuka. Ma aloyi opangidwa ndi cobalt amakhala ndi ubale wosweka ndi kutentha kwapang'onopang'ono, koma amawonetsa kukana kwa dzimbiri pakutentha kopitilira 1000 ° C kuposa kutentha kwina.

Kutentha Kutentha kwa Cobalt-based Alloys

Kukula ndi kugawa kwa tinthu tating'onoting'ono ta carbide ndi kukula kwa tirigu mu ma alloys opangidwa ndi cobalt ndizovuta kwambiri pakuponya. Kuti akwaniritse zofunika kupirira mphamvu ndi matenthedwe katundu kutopa wa kuponyedwa cobalt ofotokoza aloyi kuponya mbali, ndi kuponyera ndondomeko magawo ayenera kulamulidwa. Ma aloyi opangidwa ndi cobalt amafunikira chithandizo cha kutentha, makamaka kuti azitha kuwongolera mpweya wa carbides. Kwa ma aloyi opangidwa ndi cobalt, choyamba perekani chithandizo chamankhwala chotentha kwambiri, nthawi zambiri pa kutentha pafupifupi 1150 ° C, kuti ma carbides onse oyambira, kuphatikiza ma carbides amtundu wa MC, asungunuke kukhala njira yolimba; ndiye, chithandizo cha ukalamba chikuchitika pa 870-980 ° C. Pangani ma carbides kuyambiranso.

Magulu Odziwika a Cobalt-based Alloys

Mitundu yodziwika bwino yotengera kutentha kwa cobalt ndi: 2.4778 (malinga ndi DIN EN 10295)Hayness 188, Haynes 25 (L-605), Aloyi S-816, UMCo-50, MP-159, FSX-414, X -40, Stellite 6B, Grade 31, etc., Mitundu yaku China ndi: GH5188 (GH188), GH159, GH605, K640, DZ40M ndi zina zotero.

Kugwiritsa ntchito Cobalt-based Alloy Castings

Nthawi zambiri, cobalt-based superalloys alibe magawo olimbikitsa. Ngakhale mphamvu pa kutentha kwapang'onopang'ono ndi yotsika (50-75% yokha ya ma aloyi opangidwa ndi faifi tambala), ali ndi mphamvu zapamwamba, kukana kutopa kwamafuta, kukana abrasion, kusungunuka bwino komanso kukana kwa dzimbiri kuposa kutentha kwa 980 ° C. Chifukwa chake, ma cobalt-based alloy castings ndi oyenera kupanga ma vanenes owongolera ndi ma nozzles owongolera ma injini andege, ma turbine amafuta am'mafakitale, ma turbines apanyanja, ndi ma nozzles a injini ya dizilo, ndi zina zambiri.