Chitsulo chosapanga dzimbiri, chomwe chimatchedwanso chitsulo chosapanga dzimbiri, chimatanthawuza chitsulo cha alloy cast chomwe chimawonetsa kukana kwamphamvu kwa dzimbiri mumitundu yosiyanasiyana yazambiri zowononga kapena malo omwe dzimbiri ndi makina amakhalira.

| Kuwona Mwachangu kwa Austenitic Stainless Steel | |

| Main Chemical Composition | Cr,Ni,C,Mo,Cu,Si,Nb,Ti |

| Kachitidwe | Non-magnetic, high toughness, high plasticity, low mphamvu |

| Tanthauzo | Chitsulo chosapanga dzimbiri chokhala ndi mawonekedwe a austenitic kutentha |

| Makalasi Oyimilira | 304, 316, 1.4310, 1.4301, 1.4408 |

| Kuthekera | Zabwino |

| Weldability | Nthawi zambiri zabwino kwambiri |

| Zomwe Zimagwiritsa Ntchito | Makina azakudya, Zida Zamagetsi, Kukonza Chemical ... etc |

Chitsulo chosapanga dzimbiri chimakhala ndi chromium yochepera 10.5%, zomwe zimapangitsa kuti zisagonje ku malo owononga madzi komanso kutsekemera kwa okosijeni. Imalimbana ndi dzimbiri ndipo imasavala, imapereka makina abwino kwambiri, ndipo imadziwika bwino chifukwa cha kukongola kwake. Zopangira zitsulo zosapanga dzimbiri "zimalimbana ndi dzimbiri" zikagwiritsidwa ntchito m'malo amadzimadzi ndi nthunzi zosachepera 1200°F (650°C) ndi "zosamva kutentha" zikagwiritsidwa ntchito pamwamba pa kutenthaku.

Chitsulo chosapanga dzimbiri cha Austeniticamatanthauza chitsulo chosapanga dzimbiri chopangidwa ndi austenitic pa kutentha kwapakati. Chitsulo chosapanga dzimbiri cha Austenitic ndi chimodzi mwamagulu asanu azitsulo zosapanga dzimbiri ndi mawonekedwe a crystalline (pamodzi ndi ferritic, martensitic, duplex ndi mpweya wouma). M'madera ena, zitsulo zosapanga dzimbiri za austentite zimatchedwanso zitsulo zosapanga dzimbiri 300. Pamene chitsulo chili pafupifupi 18% Cr, 8% -25% Ni, ndi pafupifupi 0.1% C, ali khola austenite dongosolo. Chitsulo chosapanga dzimbiri cha Austenitic chromium-nickel chimaphatikizapo chitsulo chodziwika bwino cha 18Cr-8Ni ndi chitsulo chapamwamba cha Cr-Ni chopangidwa powonjezera Cr ndi Ni zomwe zili ndikuwonjezera Mo, Cu, Si, Nb, Ti ndi zinthu zina pamaziko awa. Chitsulo chosapanga dzimbiri cha Austenitic sichikhala ndi maginito ndipo chimakhala cholimba kwambiri komanso pulasitiki, koma mphamvu zake ndizochepa, ndipo sizingatheke kulimbitsa kupyolera mu kusintha kwa gawo. Ikhoza kulimbikitsidwa ndi ntchito yozizira. Ngati zinthu monga S, Ca, Se, Te ziwonjezedwa, zimakhala ndi machinability.

Chitsulo chosapanga dzimbiri cha Austenitic chimatha kupanganso ma castings. Pofuna kupititsa patsogolo kusungunuka kwachitsulo chosungunula ndi kupititsa patsogolo ntchito yoponyera, ma alloy apangidwe a zitsulo zotayidwa ayenera kusinthidwa powonjezera zitsulo za silicon, kukulitsa kuchuluka kwa chromium ndi faifi tambala, ndikuwonjezera malire apamwamba a sulfure.

Chitsulo chosapanga dzimbiri cha Austenitic chiyenera kukhala cholimba-chothetsera chisanayambe kugwiritsidwa ntchito, kuti chiwonjezere njira yolimba yazitsulo zosiyanasiyana monga carbides muzitsulo za austenite masanjidwewo, komanso homogenizing kapangidwe kake ndikuchotsa kupsinjika, kuonetsetsa kuti kukana kwa dzimbiri ndi makina katundu. Njira yoyenera yothetsera vutoli ndi kuziziritsa kwamadzi mutatha kutentha pa 1050 ~ 1150 ℃ (zigawo zopyapyala zimathanso kuziziritsidwa ndi mpweya). The njira yothetsera kutentha zimadalira mlingo wa aloyi wa zitsulo: Molybdenum-free kapena otsika-molybdenum zitsulo magiredi ayenera kukhala otsika (≤1100 ℃), ndi apamwamba aloyi sukulu monga 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, etc. ayenera kukhala apamwamba ( 1080-1150) ℃).

Chitsulo chachitsulo chosapanga dzimbiri cha Austenitic 304, chomwe chimati chimabweretsa kukana dzimbiri ndi dzimbiri, ndipo chimakhala ndi pulasitiki yabwino kwambiri komanso yolimba, yomwe ndi yabwino kupondaponda komanso kupanga. Ndi kachulukidwe ka 7.93 g / cm3, 304 chitsulo chosapanga dzimbiri ndi chitsulo chosapanga dzimbiri chodziwika bwino, chomwe chimatchedwanso 18/8 chitsulo chosapanga dzimbiri pamakampani. Zogulitsa zake zachitsulo zimagonjetsedwa ndi kutentha kwakukulu ndipo zimakhala ndi zinthu zabwino zowonongeka, choncho zimagwiritsidwa ntchito kwambiri m'mafakitale ndi mafakitale okongoletsera mipando ndi mafakitale a zakudya ndi zamankhwala.

Gulu Lofanana la Chitsulo Chosapanga dzimbiri | |||||||

| Magulu | AISI | W-otsika | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ndi Ferritic Stainless Steel | 420C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | Chithunzi cha X42KR13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 ndi 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | 7Kr14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 KL13 | 405 ndi 17 | - | F.3111 | X6 KL13 | |

| 416 | 1.4005 | Chithunzi cha X12 CrS 13 | 416 ndi 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | 6Kr17 | 430 ndi 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | Chithunzi cha X20KR13 | 420 ndi 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | Chithunzi cha X30KR13 | 420 ndi 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 ndi 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 ndi 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 ndi 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 ndi 17 | - | - | X6CrTi12 | |

| Chitsulo chosapanga dzimbiri cha Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 ndi 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 ndi 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 ndi 21 | 2346 | F.3508 | Chithunzi cha X10CrNiS 1809 | |

| 304l pa | 1.4306 | X2 CrNiS 18 9 | 304 ndi 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 ndi 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 ndi 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 ndi 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 ndi 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316l ndi | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316l ndi | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 ndi 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317l ndi | 1.4438 | X2 CrNiMo 18 16 | 317 ndi 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 ndi 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 ndi 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 ndi | 1.4571 | X10 CrNiMoTi 18 10 | 320 ndi 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 ndi 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Chitsulo chosapanga dzimbiri cha Duplex | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Zida Zachitsulo ndi Zopanda ferrous Poponya Ndalama, Njira Yotayira Sera:

- • Iron Yotuwa: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Ductile Iron kapena Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Zitsulo zachitsulo: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc popempha.

- • Chitsulo Chosapanga dzimbiri: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ndi kalasi ina yosapanga dzimbiri.

- • Brass, Red Copper, Bronze kapena zitsulo zina za Copper-based alloy: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Zida Zina malinga ndi zofunikira zanu zapadera kapena malinga ndi ASTM, SAE, AISI, ACI, DIN, EN, ISO, ndi GB miyezo

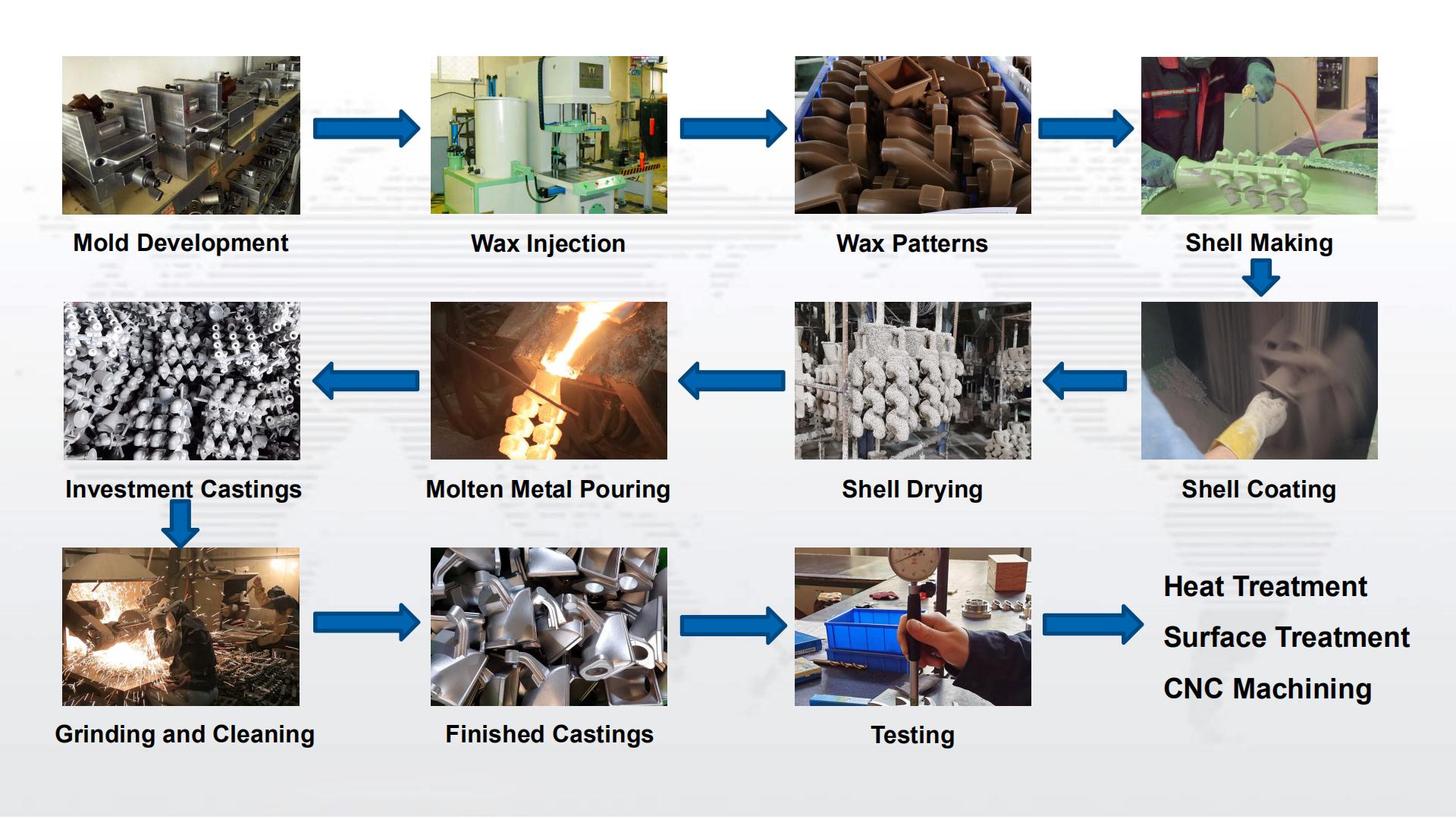

Masitepe omwe akukhudzidwa ndi ndondomekoyi kapena kutaya phula kotayika ndi:

- • Pangani chitsanzo cha sera kapena chofananira

- • Phulitsani chitsanzo cha sera

- • Ikani ndondomeko ya sera

- • Chotsani ndondomeko ya sera poyiwotcha (mkati mwa ng'anjo kapena m'madzi otentha) kuti mupange nkhungu.

- • Limbikitsani zitsulo zosungunuka kutsanulira mu nkhungu

- • Kuzizira ndi Kukhazikika

- • Chotsani sprue kuchokera ku castings

- • Malizitsani ndi kupukuta zomwe zatsirizidwa

Chithandizo cha kutentha kwa AISI 316 Stainless Steel Castings:

Kutenthetsa mpaka 1900 ° F (1040 ° C) osachepera, kugwira nthawi yokwanira, kuzimitsa m'madzi kapena kuzizira mofulumira ndi njira zina. AISI 316 yofanana ndi CF8M/F316 ndi Chinese Standard 0Cr17Ni12Mo2. AISI 314 ndi molybdenum yokhala ndi kusinthidwa kwa AISI 304 alloy ndipo ndiyofanana ndi CF8M Stainless steel yopangidwa. Kukhalapo kwa molybdenum kumawonjezera kukana kwa dzimbiri komanso kukana kupindika ndi ma chloride. Aloyi amagwiritsidwa ntchito mu acidic pang'ono komanso zamchere komanso pogwira citric, oxalic ndi phosphoric acid.