2205 duplex zitsulo zosapanga dzimbiri ndi duplex zitsulo zosapanga dzimbiri zopangidwa ndi 21% chromium, 2.5% molybdenum ndi 4.5% nickel-nitrogen alloy. Mitundu ya ferrite ndi austenite iliyonse imakhala pafupifupi 50%. Lili ndi mphamvu zambiri, kulimba kwabwino komanso kulimba mtima kwapadziko lonse komanso kukana kupsinjika kwapanyumba. Mphamvu zokolola za 2205 duplex zitsulo zosapanga dzimbiri ndizowirikiza kawiri kuposa chitsulo chosapanga dzimbiri cha austenitic. Izi zimathandiza opanga kuchepetsa kulemera popanga zinthu, zomwe zimapangitsa kuti alloy iyi ikhale yotsika mtengo kuposa 316 ndi 317L. Aloyiyi ndi yoyenera kwambiri kutentha kwa -50°F/+600°F. Pazogwiritsa ntchito mopitilira kutentha uku, alloy iyi imathanso kuganiziridwa, koma pali zoletsa zina, makamaka zikagwiritsidwa ntchito pamipangidwe yowotcherera.

Poyerekeza ndi 316L ndi 317L austenitic chitsulo chosapanga dzimbiri, 2205 duplex chitsulo chosapanga dzimbiri chili ndi ntchito yabwino kwambiri yolimbana ndi dzimbiri komanso kuphulika kwa minga. Ili ndi kukana kwa dzimbiri kwapamwamba. Poyerekeza ndi austenitic, ake The coefficient of thermal expansion ndi otsika ndipo matenthedwe conductivity ndi apamwamba. Poyerekeza ndi chitsulo chosapanga dzimbiri cha austenitic, chitsulo chosapanga dzimbiri cha duplex 2205 alloy chimakhala ndi mphamvu zopondereza kawiri. Poyerekeza ndi 316L ndi 317L, wopanga akhoza kuchepetsa kulemera kwake. Aloyi 2205 makamaka oyenera kutentha osiyanasiyana -50°F/+600°F. Pansi pa zoletsa zokhwima (makamaka zopangira zowotcherera), zitha kugwiritsidwanso ntchito potentha kwambiri.

Duplex zitsulo zosapanga dzimbiriamatanthawuza zitsulo zopangidwa ndi duplex zosapanga dzimbiri. Duplex Stainless Steel (DSS) imatanthawuza chitsulo chosapanga dzimbiri chokhala ndi ferrite ndi austenite iliyonse yowerengera pafupifupi 50%. Nthawi zambiri, zomwe zili m'magawo ocheperako ziyenera kukhala zosachepera 30%. Pankhani ya C yotsika, Cr zili 18% mpaka 28%, ndipo Ni zili 3% mpaka 10%. Zitsulo zina zosapanga dzimbiri zosapanga dzimbiri zimakhalanso ndi zinthu monga Mo, Cu, Nb, Ti, ndi N.

DSS ili ndi mawonekedwe a austenitic ndi ferritic chitsulo chosapanga dzimbiri. Poyerekeza ndi ferrite, ili ndi pulasitiki wapamwamba komanso ductility, palibe kutentha kwa chipinda, komanso kupititsa patsogolo kukana kwa dzimbiri kwa intergranular ndi kuwotcherera, ndikusungabe brittleness, matenthedwe apamwamba, komanso superplasticity ngati chitsulo chosapanga dzimbiri. Poyerekeza ndi chitsulo chosapanga dzimbiri cha austenitic, DSS ili ndi mphamvu zambiri komanso imathandizira kwambiri kukana kwa intergranular corrosion ndi chloride stress corrosion. Chitsulo chosapanga dzimbiri cha Duplex chimakhala ndi chitsulo chosapanga dzimbiri komanso chitsulo chosapanga dzimbiri.

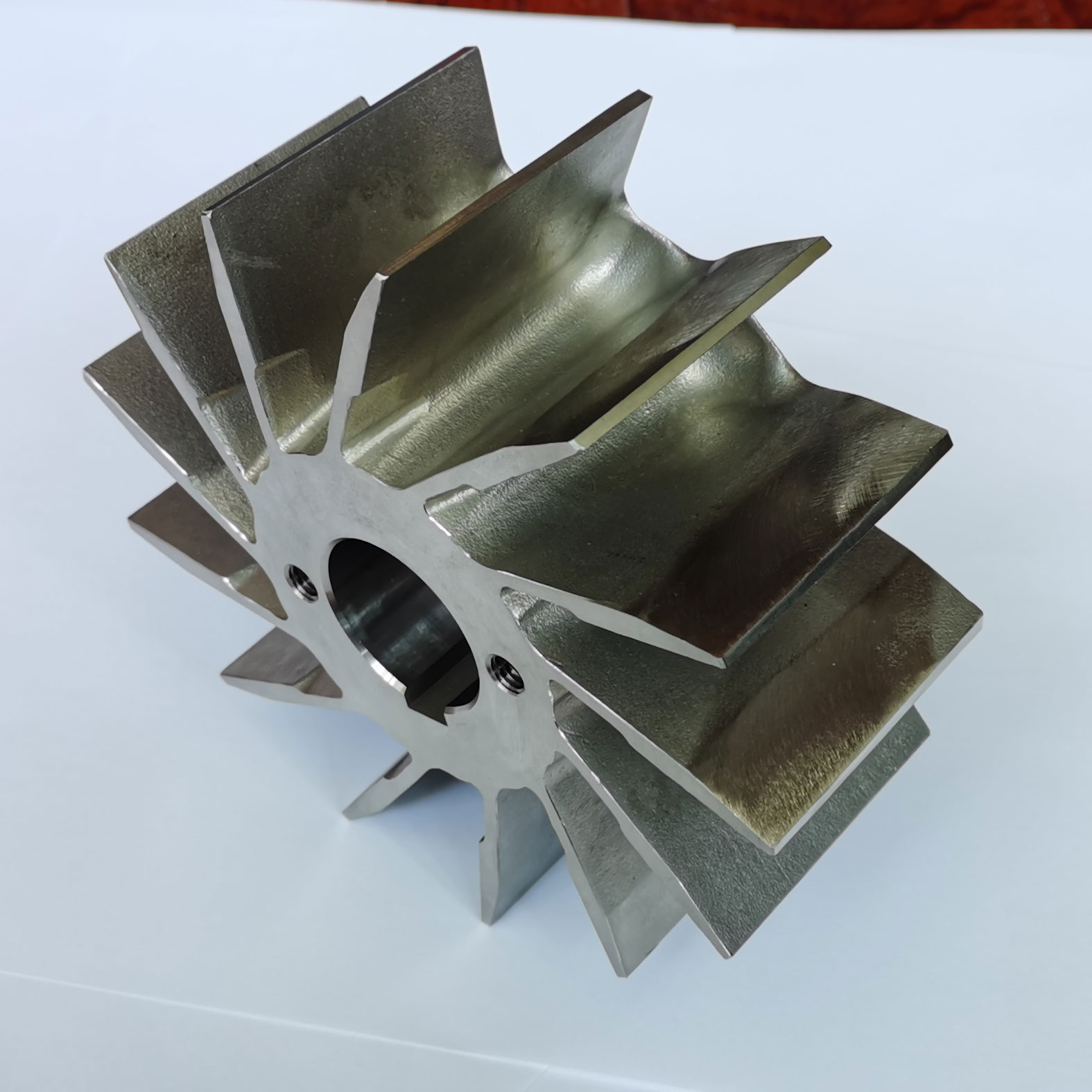

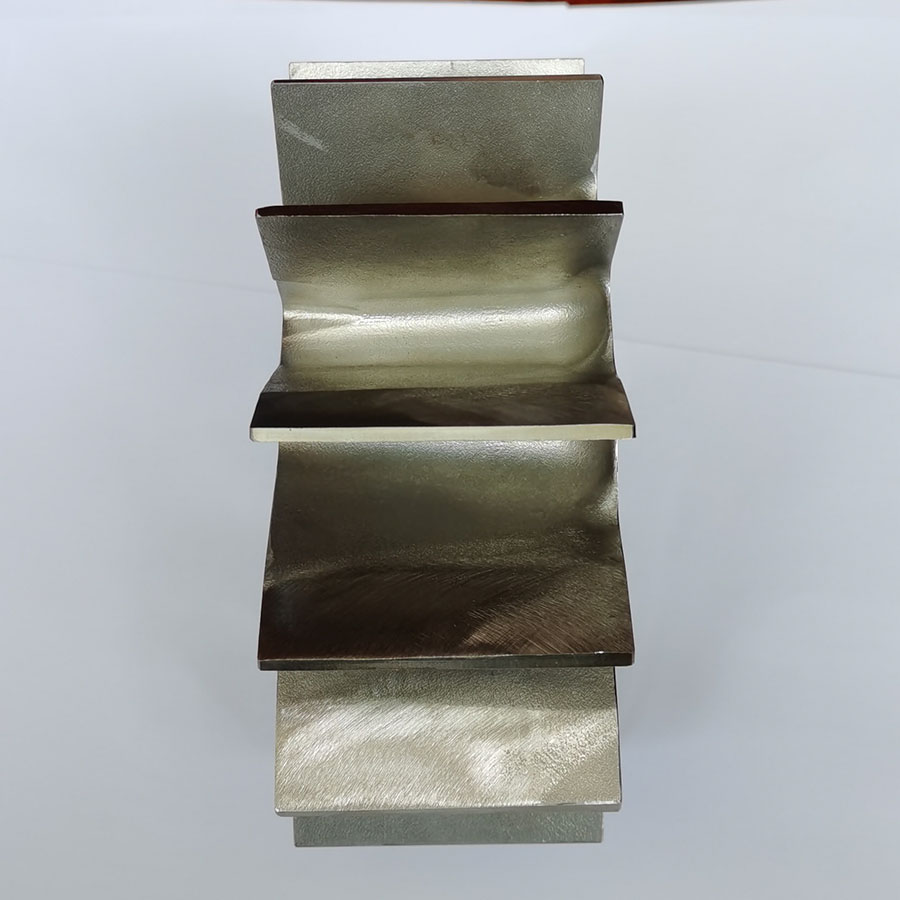

Popanga zitsulo, zitsulo zambiri zosapanga dzimbiri zimamalizidwa ndikuponya ndalama. Pamwamba pazitsulo zosapanga dzimbiri zopangidwa ndi kuponyedwa kwa ndalama ndizosavuta komanso kulondola kwazithunzi ndikosavuta kuwongolera. Inde, mtengo wandalama kuponyera zitsulo zosapanga dzimbirindi okwera poyerekeza ndi njira zina ndi zipangizo.

▶ Maluso aInvestment Casting Foundry

• Kukula Kwambiri: 1,000 mm × 800 mm × 500 mm

• Kulemera kwake: 0,5 kg - 100 kg

• Mphamvu Zapachaka: matani 2,000

• Zida Zomangamanga Zomanga Zipolopolo: Silica Sol, Madzi Glass ndi zosakaniza zake.

• Kulekerera: Popempha.

▶ Main Production Procedure of Investment Casting

• Pangani chitsanzo cha sera kapena chofananira

• Phulitsani chitsanzo cha sera

• Ikani ndondomeko ya sera

• Chotsani ndondomeko ya sera poyiwotcha (mkati mwa ng'anjo kapena m'madzi otentha) kuti mupange nkhungu.

• Limbikitsani zitsulo zosungunuka kutsanulira mu nkhungu

• Kuzizira ndi Kukhazikika

• Chotsani sprue kuchokera ku castings

• Malizitsani ndi kupukuta zomwe zatsirizidwa