Custom castduplex zitsulo zosapanga dzimbiri zoponyera ndalamakuchokera ku China kuponyera maziko okhala ndi makina, chithandizo cha kutentha, ndi ntchito zochizira pamwamba.

Chithunzi cha RMCmwatsatanetsatane kuponyedwa zitsulo mbalizomwe zimakwaniritsa kapena kupitilira zomwe makasitomala amayembekezera. Kutaya ndalama zotayira sera kumatithandiza kupanga zitsulo zazing'ono ngati magalamu khumi ndi zazikulu ngati ma kilogalamu khumi, mumitundu yambiri ya aloyi achitsulo komanso opanda ferrous komanso molondola mwapadera.

Kuponyera sera kotayika kumapanga zigawo zachitsulo zowoneka bwino kwambiri zomwe nthawi zambiri zimafuna kukonza pang'ono kapena osafunikira. Zotsatira zake zimakhalanso zabwino kwambiri kuposa zomwe zimatheka kudzera munjira zina. Kulimba ndi kulimba kwa magawo oponyera amadzipanga kukhala abwino kwambiri okana kuvala omwe amafunikira mizere yozungulira.

Duplex Stainless Steel (DSS) imatanthawuza chitsulo chosapanga dzimbiri chokhala ndi ferrite ndi austenite iliyonse yowerengera pafupifupi 50%. Nthawi zambiri, zomwe zili m'magawo ocheperako ziyenera kukhala zosachepera 30%. Pankhani ya C yotsika, Cr zili 18% mpaka 28%, ndipo Ni zili 3% mpaka 10%. Zitsulo zina zosapanga dzimbiri zosapanga dzimbiri zimakhalanso ndi zinthu monga Mo, Cu, Nb, Ti, ndi N.

Kupezeka kwa duplex zitsulo zosapanga dzimbiri pa RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, A 890, 5 A8 A9A 3A 3A 890, 8 A9 A9, 8 A9 A9, 8 A9 A9, 890, 8 A9 A9. 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS ili ndi mawonekedwe a austenitic ndi ferritic chitsulo chosapanga dzimbiri. Poyerekeza ndi ferrite, ili ndi pulasitiki wapamwamba komanso ductility, palibe kutentha kwa chipinda, komanso kupititsa patsogolo kukana kwa dzimbiri kwa intergranular ndi kuwotcherera, ndikusungabe brittleness, matenthedwe apamwamba, komanso superplasticity ngati chitsulo chosapanga dzimbiri. Poyerekeza ndi chitsulo chosapanga dzimbiri cha austenitic, DSS ili ndi mphamvu zambiri komanso imathandizira kwambiri kukana kwa intergranular corrosion ndi chloride stress corrosion. Chitsulo chosapanga dzimbiri cha Duplex chimakhala ndi chitsulo chosapanga dzimbiri komanso chitsulo chosapanga dzimbiri.

| Gulu Lofanana la Chitsulo Chosapanga dzimbiri | |||||||

| MABUKU | AISI | W-otsika | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic ndi Ferritic Stainless Steel | 420C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | Chithunzi cha X42KR13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 ndi 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | 7Kr14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 KL13 | 405 ndi 17 | - | F.3111 | X6 KL13 | |

| 416 | 1.4005 | Chithunzi cha X12 CrS 13 | 416 ndi 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | 6Kr17 | 430 ndi 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | Chithunzi cha X20KR13 | 420 ndi 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | Chithunzi cha X30KR13 | 420 ndi 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 ndi 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 ndi 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 ndi 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 ndi 17 | - | - | X6CrTi12 | |

| Chitsulo chosapanga dzimbiri cha Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 ndi 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 ndi 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 ndi 21 | 2346 | F.3508 | Chithunzi cha X10CrNiS 1809 | |

| 304l pa | 1.4306 | X2 CrNiS 18 9 | 304 ndi 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 ndi 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 ndi 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 ndi 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 ndi 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316l ndi | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316l ndi | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 ndi 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317l ndi | 1.4438 | X2 CrNiMo 18 16 | 317 ndi 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 ndi 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 ndi 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 ndi | 1.4571 | X10 CrNiMoTi 18 10 | 320 ndi 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 ndi 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Chitsulo chosapanga dzimbiri cha Duplex | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

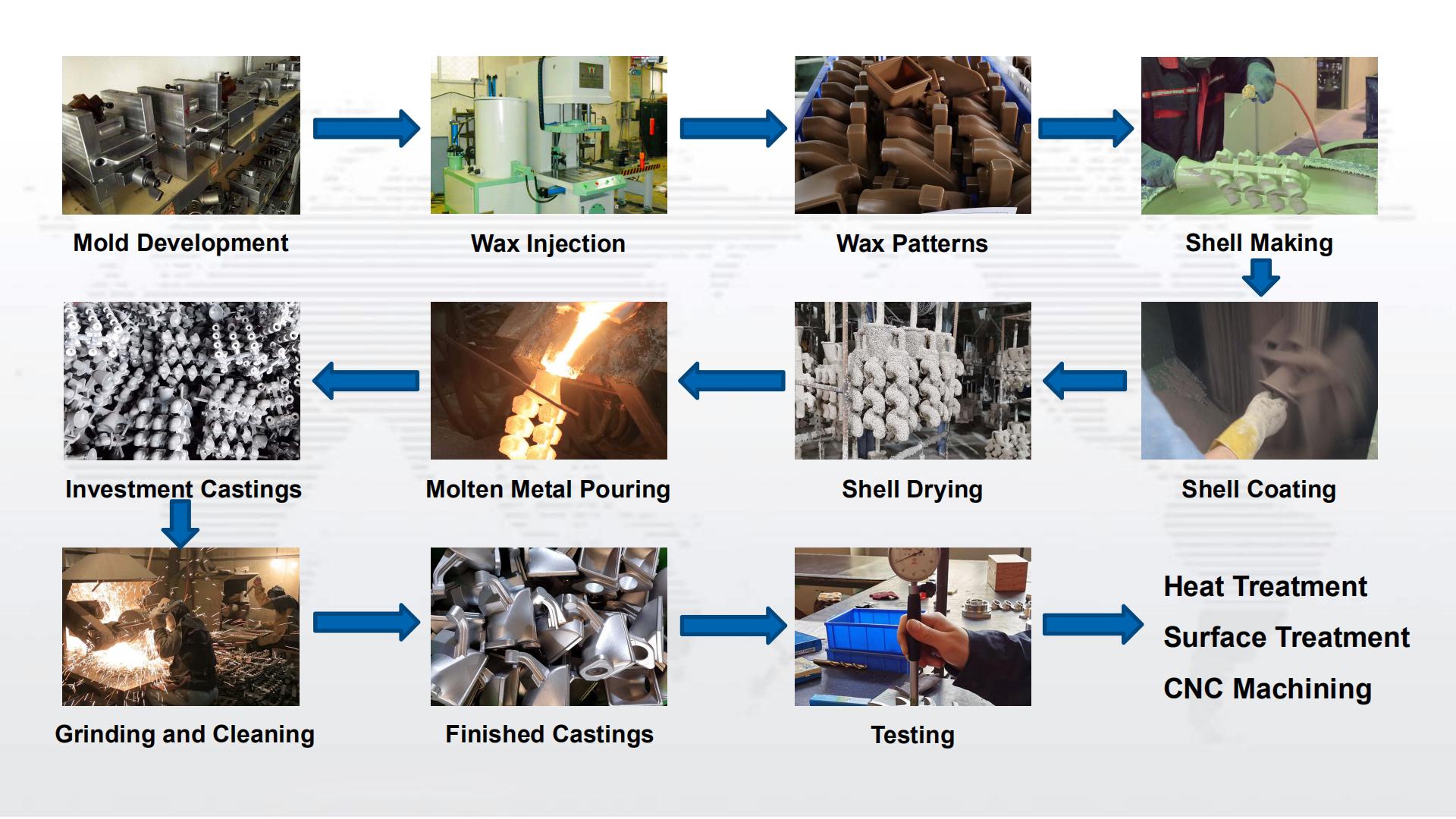

▶ Zitsulo za Ferrous ndi Zopanda chitsulo zaInvestment Casting, Njira Yotayira Sera:

• Iron Yotuwa: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron kapena Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Zitsulo zachitsulo: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc popempha.

• Chitsulo Chosapanga dzimbiri: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 ndi kalasi ina yosapanga dzimbiri.

• Brass, Red Copper, Bronze kapena zitsulo zina za Copper-based alloy: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Zida Zina malinga ndi zofunikira zanu zapadera kapena malinga ndi ASTM, SAE, AISI, ACI, DIN, EN, ISO, ndi GB miyezo

▶ Maluso aInvestment Casting Foundry

• Kukula Kwambiri: 1,000 mm × 800 mm × 500 mm

• Kulemera kwake: 0,5 kg - 100 kg

• Mphamvu Zapachaka: matani 2,000

• Zida Zomangamanga Zomanga Zipolopolo: Silica Sol, Madzi Glass ndi zosakaniza zake.

| Ntchito | Kufotokozera |

| Surface Treatment Services | Kupaka ufa, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, etc. |

| CNC Precision Machining Services | Lathing, mphero, Kutembenuza, Honing, kubowola, Boring, Kugogoda, Waya Electrode Kudula, Kupera ... etc. |

| Kuyang'anira ndi Kuwongolera Ubwino | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Seiling Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester ... etc. |