Grey cast iron mankhwala ndimchenga nkhungu kuponyera ndondomekondi CNC Machining.

Iron cast iron imatchedwa mtundu wa imvi wa fracture yomwe imapanga. Chitsulo cha imvi chimagwiritsidwa ntchito popanga nyumba zomwe kuuma kwa chigawocho kuli kofunika kwambiri kuposa mphamvu zake zowonongeka, monga zitsulo zamkati za injini zoyaka moto, nyumba zapampu, matupi a valve, mabokosi amagetsi, zolemera zowerengera ndi zokongoletsera zokongoletsera. Matenthedwe apamwamba a chitsulo cha Grey cast ndi mutu wake nthawi zambiri amagwiritsidwa ntchito popanga zophikira zachitsulo ndi ma disc brake rotor.

Zomwe zimapangidwira kuti mupeze graphic microstructure ndi 2.5 mpaka 4.0% carbon ndi 1 mpaka 3% silicon polemera. Graphite amatha kutenga 6 mpaka 10% ya voliyumu yachitsulo chotuwa. Silicon ndi yofunika kupanga chitsulo imvi mosiyana ndi chitsulo choyera, chifukwa silicon ndi graphite stabilizing element mu iron cast, kutanthauza kuti amathandiza alloy kupanga graphite m'malo carbides chitsulo; pa 3% silicon pafupifupi palibe mpweya umene umakhala ndi mankhwala osakaniza ndi chitsulo.

graphite amatenga mawonekedwe a mbali zitatu za flake. M'miyeso iwiri, ngati malo opukutidwa adzawonekera pansi pa maikulosikopu, ma graphite flakes amawoneka ngati mizere yabwino. Nsonga za flakes zimagwira ntchito ngati nsonga zakale; kotero, ndi brittle. Kukhalapo kwa ma graphite flakes kumapangitsa Grey Iron kuti ikhale yosavuta kupanga chifukwa imakonda kusweka mosavuta kudutsa ma graphite flakes. Chitsulo chotuwira chimakhalanso ndi mphamvu yabwino yonyowetsa, chifukwa chake chimagwiritsidwa ntchito kwambiri ngati maziko oyika zida zamakina.

Grey Cast Iron Mechanical Properties | |||||||

| Zinthu molingana ndi DIN EN 1561 | Yesani | Chigawo | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | Chithunzi cha EN-JL 1030 | Chithunzi cha EN-JL1040 | Mtengo wa EN-JL 1050 | Chithunzi cha EN-JL1060 | |||

| Kulimba kwamakokedwe | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Mphamvu Zokolola | rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Mphamvu | A | % | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 | 0, 3 - 0, 8 |

| Compressive Mphamvu | σdB ndi | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Compressive Mphamvu | s0, 1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Mphamvu | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Ma modules a elasticity | E | GPA | 78-103 | 88-113 | 103-118 | 108-137 | 123-143 |

| Poisson nambala | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell kuuma | HB | 160-190 | 180-220 | 190-230 | 200-240 | 210-250 | |

| Ductility | σbw | MPa | 70 | 90 | 120 | 140 | 145 |

| Kupanikizika ndi kupanikizika kumasintha | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Kuphwanya Mphamvu | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Kuchulukana | g/cm3 | 7, 10 | 7, 15 | 7,20 | 7, 25 | 7,30 | |

Kuponyera mchenga kumagwiritsa ntchito mchenga wobiriwira (mchenga wonyowa) kapena mchenga wouma kupanga makina owumba. Kuponyera mchenga wobiriwira ndi njira yakale yoponyera yomwe imagwiritsidwa ntchito m'mbiri. Popanga nkhungu, mapangidwe opangidwa ndi matabwa kapena zitsulo ayenera kupangidwa kuti apange dzenje. Chitsulo chosungunulacho chimatsanulira mu mtsempha kuti apange zoponyera pambuyo pozizira ndi kulimba. Kuponya mchenga ndikotsika mtengo kuposa njira zina zopangira nkhungu komanso gawo loponyera ma unit. Mchenga kuponyera, nthawizonse zikutanthauza wobiriwira mchenga kuponyera (ngati palibe kufotokoza wapadera). Komabe, masiku ano, njira zina zoponyamo zimagwiritsanso ntchito mchenga kupanga nkhungu. Ali ndi mayina awoawo, mongachipolopolo nkhungu kuponyera, utomoni wa furan wokutira mchenga (palibe mtundu wophika),kutaya thovundi kuponya vacuum.

Mphamvu Zoponya Mchenga ku RMC Foundry | ||

| Kufotokozera | Kuumba ndi Manja | Kumanga ndi Makina Odzipangira okha |

| Kukula kwakukulu kwa Castings | 1,500 mamilimita × 1000 mamilimita × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Casting Weight Range | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Kukhoza Pachaka | 5,000 matani - 6,000 matani | 8,000 matani - 10,000 matani |

| Kulekerera Kutaya | Pa Pempho kapena Muyezo (ISO8062-2013 kapena GB/T 6414-1999) | |

| Zida Zomangira | Mchenga Wobiriwira, Mchenga Wokutidwa ndi Resin | |

| Kuponyera Zitsulo & Aloyi | Gray Iron, Ductile Iron, Cast Steel, Stainless Steel, Al Alloys, Brass, Bronze... etc. | |

Ubwino wa Sand Casting:

- ✔ Mtengo Wotsika chifukwa cha nkhungu zake zotsika mtengo komanso zobwezerezedwanso komanso zida zosavuta zopangira.

- ✔ Kulemera kwa ma unit osiyanasiyana kuchokera ku 0,10 kg mpaka 500 kgs kapena kupitilira apo.

- ✔ Mapangidwe Osiyanasiyana kuchokera ku mtundu wosavuta kupita ku mtundu wovuta.

- ✔ Zoyenera kupanga zamitundu yosiyanasiyana.

Kulekerera Komwe Kutulutsa Mchenga Kumapindula:

Zololera zoponya zimagawidwa mu Dimensional Casting Tolerances (DCT) ndi Geometrical Casting Tolerances (GCT). Woyambitsa wathu akufuna kulankhula nanu ngati muli ndi pempho lapadera pazoyenera kulekerera. Apa m'munsimu muli kalasi yololera yomwe titha kufikira poponya mchenga wobiriwira, kuponyera nkhungu za zipolopolo ndi kuponyera mchenga wa furan resin:

- ✔ Gulu la DCT ndi Green Sand Casting: CTG10 ~ CTG13

- ✔ DCT Kalasi ndi Shell Mold Casting kapena Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Gulu la GCT ndi Green Sand Casting: CTG6 ~ CTG8

- ✔ Gulu la GCT lopangidwa ndi Shell Mold Casting kapena Furan Resin Sand Casting: CTG4 ~ CTG7

Gawo la Metal & Alloys la Njira Zoponyera Mchenga | |

| Zitsulo & Aloyi | Gulu Lotchuka |

| Gray Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ductile (Nodualar) Cast Iron | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Chitsulo cha Carbon | C20, C25, C30, C45 |

| Aloyi Chitsulo | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Chitsulo chosapanga dzimbiri | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Mpweya Woumitsa Chitsulo chosapanga dzimbiri, Duplex Stainless Steel |

| Aluminiyamu Aloyi | ASTM A356, ASTM A413, ASTM A360 |

| Ma Aloyi a Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, ndi GB | |

-

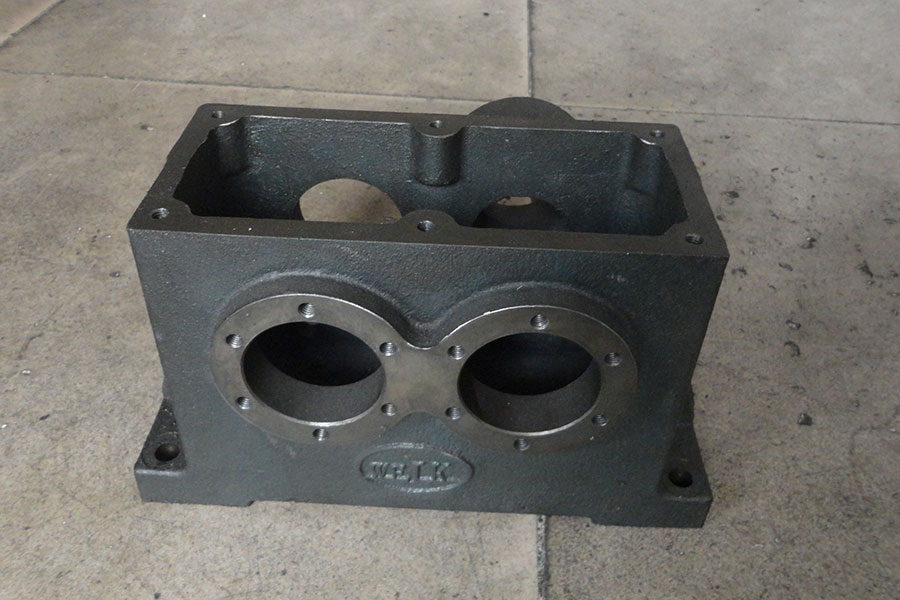

Grey Cast Iron Sand Casting Product

-

Gray Cast Iron Shell Casting Product

-

OEM Gray Cast Iron Casting

-

Aloyi Zitsulo Resin wokutidwa Mchenga Kuponya Crankshaft

-

Alloy Steel Sand Castings

-

Magawo a Alloy Steel Truck by Sand Casting ndi CNC...

-

Kampani ya Carbon Steel Sand Casting Company

-

Cast Steel Sand Casting

-

Aluminium Alloy Sand Casting