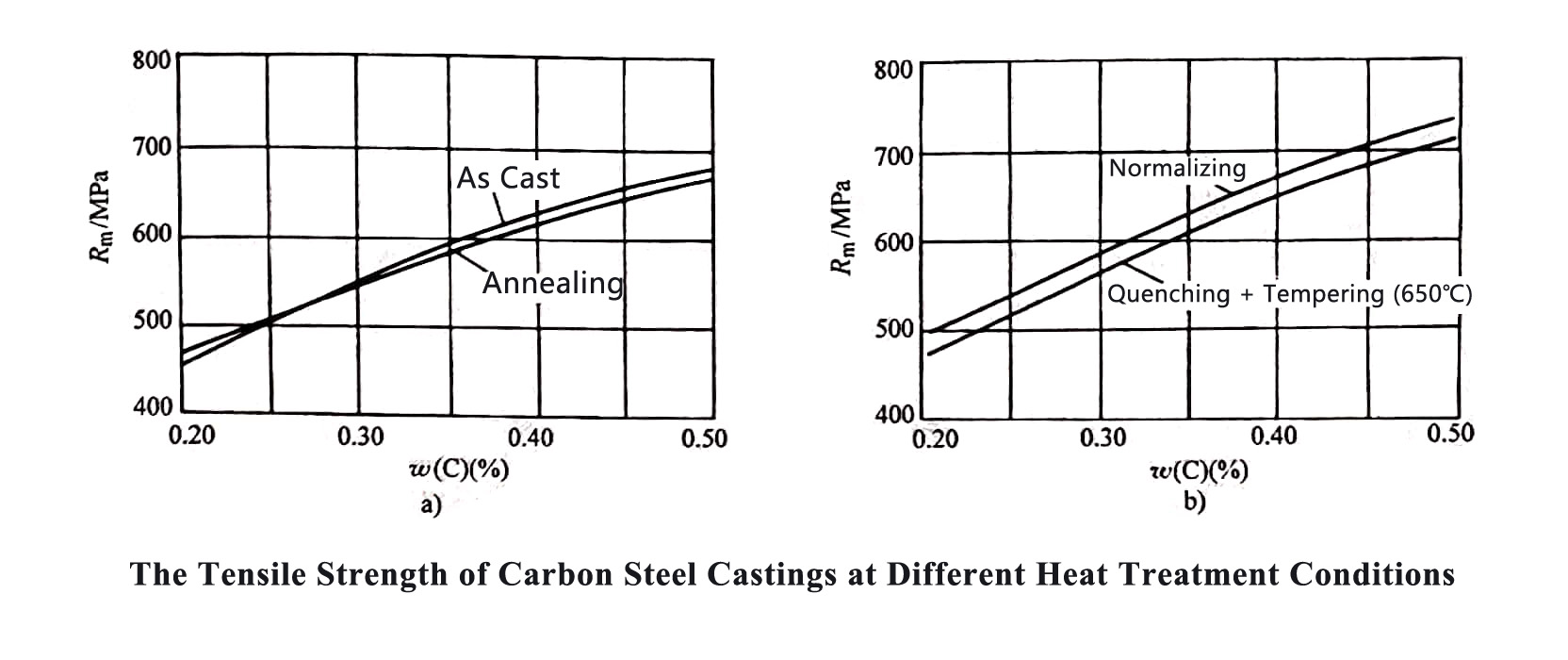

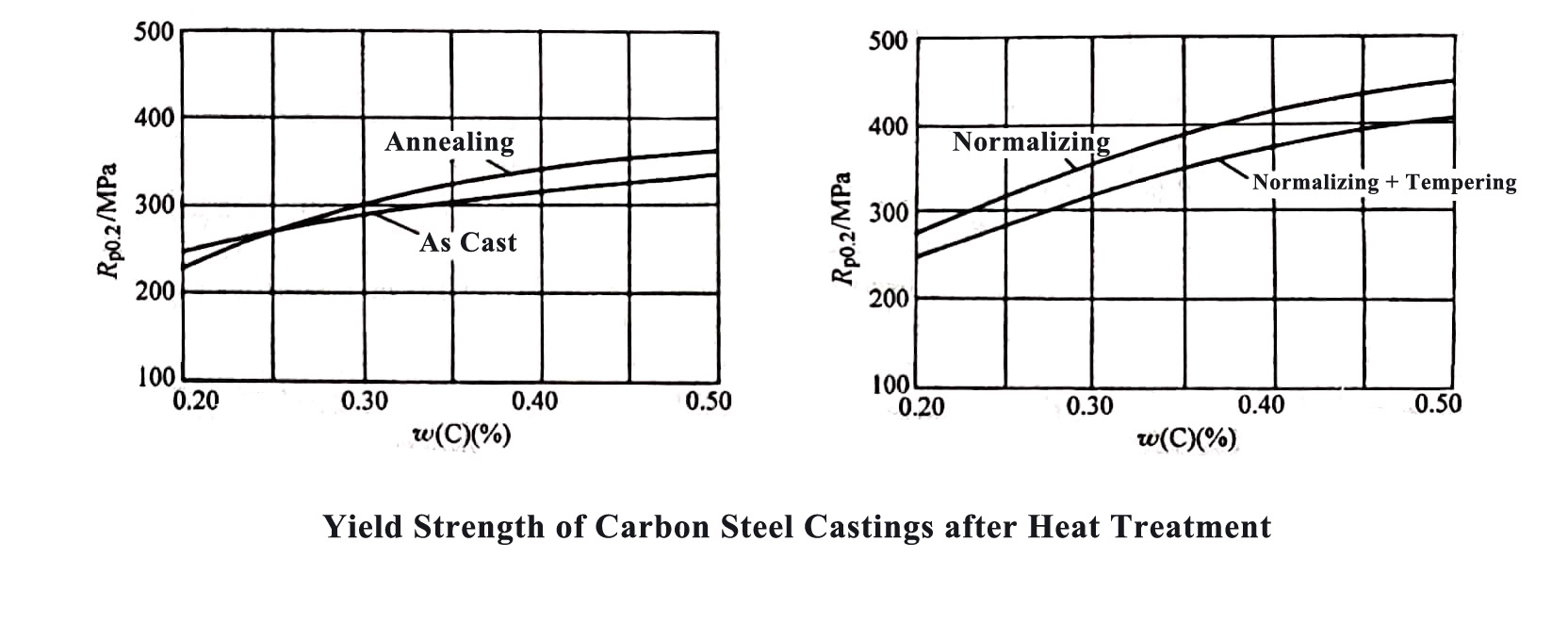

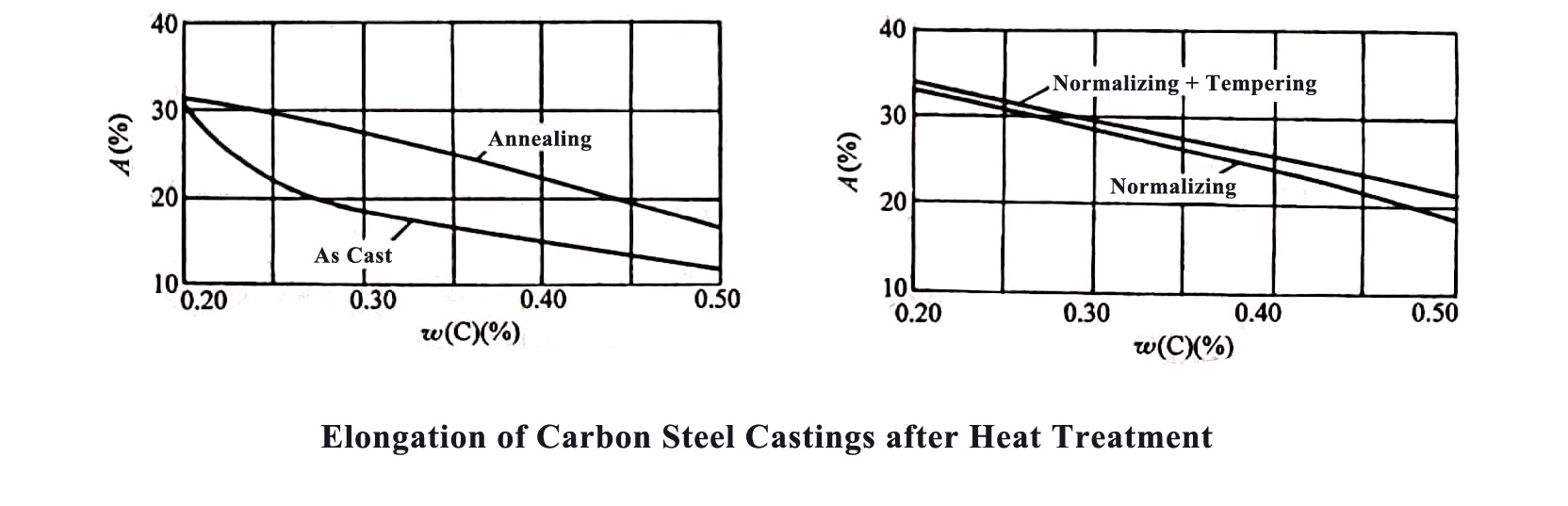

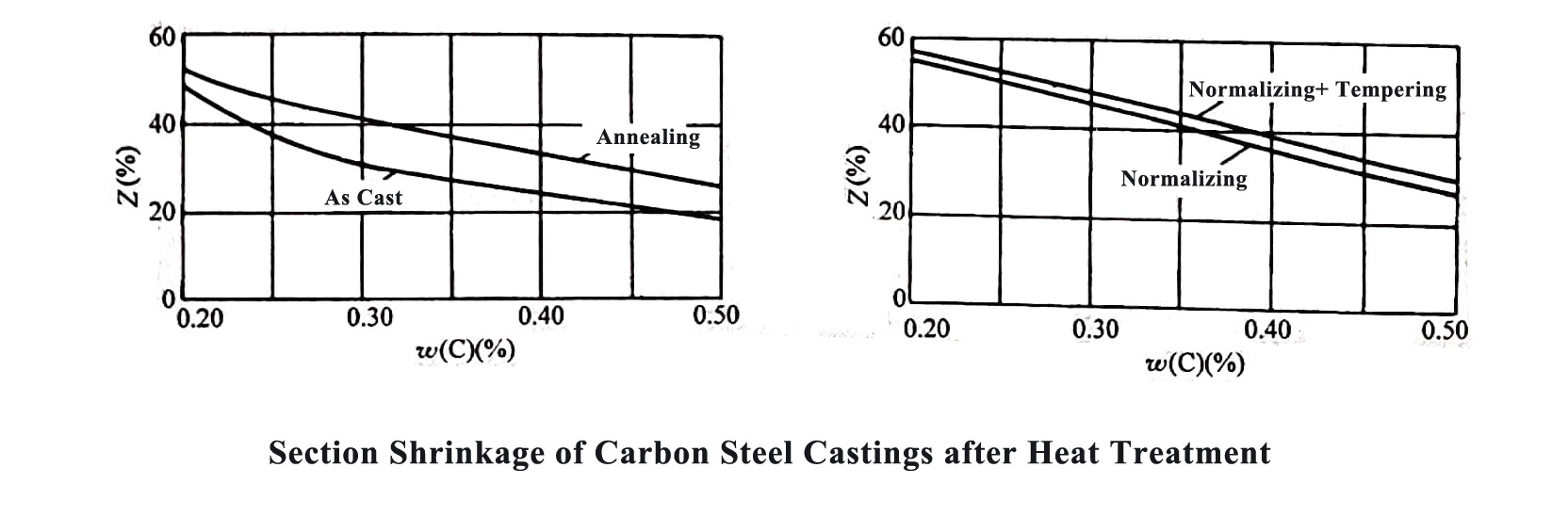

Njira zochizira kutentha zomwe zimagwiritsidwa ntchito popanga zitsulo za kaboni ndi: annealing, normalizing kapena normalizing + tempering. Chikoka cha njira zitatu zochizira kutentha pazitsulo zamakina a carbon steel zikuwonetsedwa mu chithunzi pansipa.

| Kutentha Kwambiri ndi Kuuma kwa Carbon Steel Castings | ||||||

| Gulu la Carbon Steel | Mpweya wa Mpweya / % | Kutentha kwa Annealing / ℃ | Kusunga Nthawi | Njira Yozizirira | Kulimba / HBW | |

| Makulidwe a Khoma / mm | Nthawi / h | |||||

| ZG200-400 | 0.10 - 0.20 | 910-880 | < 30 | 1 | Kuzizira mpaka 620 ℃ m'ng'anjo ndikuzizira mumlengalenga | 115-143 |

| ZG230 - 450 | 0.20 - 0.30 | 900-870 | 133-156 | |||

| ZG270-500 | 0.30 - 0.40 | 890-860 | 143-187 | |||

| Mtengo wa ZG310-570 | 0.40 - 0.50 | 870-840 | 30-100 | onjezerani 1 ora / 30 mm | 156-127 | |

| ZG340 - 640 | 0.50 - 0.60 | 860-830 | 187-230 | |||

The makina katundu wa normalized kuponyedwa zitsulo ndi apamwamba pang'ono kuposa annealed kuponyedwa zitsulo. Monga momwe kuchuluka kwa kuzizira panthawi ya kusintha kwapangidwe kumakhala kwakukulu, kuuma kudzakhala kwakukulu, ndipo ntchito yake yodula imakhalanso yabwino.

| Kukhazikika ndi Kuuma kwa Carbon Steel Castings | |||||

| Gulu la Carbon Steel | Mpweya wa Mpweya (%) | Normalizing Kutentha / ℃ | Kutentha | Kulimba / HBW | |

| Kutentha / ℃ | Njira Yozizirira | ||||

| ZG200-400 | 0.10 - 0.20 | 930-890 | 540 - 610 | m'ng'anjo kapena mpweya | 126-149 |

| ZG230 - 450 | 0.20 - 0.30 | 930-890 | 540 - 610 | m'ng'anjo kapena mpweya | 139-169 |

| ZG270-500 | 0.30 - 0.40 | 890-860 | 550 - 620 | m'ng'anjo kapena mpweya | 149-187 |

| Mtengo wa ZG310-570 | 0.40 - 0.50 | 890-850 | 550-650 | m'ng'anjo kapena mpweya | 163-217 |

| ZG340 - 640 | 0.50 - 0.60 | 870-830 | 550-650 | m'ng'anjo kapena mpweya | 187-228 |

Kwa carbon steel castings yokhala ndi mpweya wambiri komanso mawonekedwe ovuta, kuti athetse kupsinjika kotsalira ndikuwongolera kulimba, chithandizo cha kutentha chikhoza kuchitika pambuyo pokhazikika. Kutentha kotentha nthawi zambiri kumakhala 550 ℃-650 ℃, kenako kuzizira mumlengalenga.

Pamene mpweya wokhutira ndi apamwamba kuposa 0,35%, ndi kuponyedwa mpweya zitsulo mbali angathe kuzimitsidwa ndi kupsya mtima (zimitsidwa + kutentha kutentha). Small carbon zitsulo castings akhoza mwachindunji kuzimitsidwa ndi kupsa mtima mu monga-kuponyedwa boma; zazikulu kapena zovuta zoboola pakati zitsulo za carbon zitsulo ziyenera kuzimitsidwa ndi kutenthedwa pambuyo pokhazikika.

| Kutentha ndi Kutentha Kwambiri ndi Kuuma kwa Carbon Steel Castings | |||

| Kaboni % | Kutentha Kwambiri / ℃ | Kutentha Kutentha / ℃ | Kuuma Pambuyo Kutentha / HBW |

| 0.35 - 0.45 (Kagulu Kang'ono) | 850 - 830 (Kuzizira M'madzi) | 300-400 | 364-444 |

| 400-450 | 321-415 | ||

| 510 - 550 | 241-286 | ||

| 540-580 | 228-269 | ||

| 580-640 | 192-228 | ||

| 0.45 - 0.55 (Kagulu Kang'ono) | 830 - 810 (Kuzizira M'madzi Kapena Mafuta) | 550 - 630 | 220-240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Mgulu la Misa) | 840 -880 (Kuzizira M'madzi Kapena Mafuta) | 520-550 | 229-269 |

| 530-560 | 217-255 | ||

| 540 - 570 | 207-241 | ||

| 550 - 580 | 187-229 | ||

| 0.40 - 0.50 (Mgulu la Misa) | 820 - 840 (Kuzizira M'madzi Kapena Mafuta) | 530-560 | 229-269 |

| 550 - 580 | 217-255 | ||

| 560-590 | 207-241 | ||

| 570-600 | 187-229 | ||

Nthawi yotumiza: Jul-23-2021