RMC ndi malo opangira zitsulo zosapanga dzimbiri ku China kuti mukhale ndi zitsulo zosapanga dzimbiri zomwe zimapangidwa molingana ndi zojambula zanu ndi zofunikira zanu, zomwe zimagwiritsidwa ntchito pa disc valve ya butterfly.

CNC Machining amatanthauza njira yopangira makina opangidwa ndi Computerized Numberical Control (CNC mwachidule). Imathandizidwa ndi CNC kuti ifike pakulondola kwambiri komanso kosasunthika ndi ndalama zochepa zogwirira ntchito. Machining ndi njira iliyonse yosiyana yomwe chidutswa cha zinthu zopangira chimadulidwa mu mawonekedwe omaliza omwe amafunidwa ndi kukula kwake ndi njira yoyendetsedwa yochotsa zinthu. Njira zomwe zili ndi mutu wofanana, kuchotsedwa kwazinthu zoyendetsedwa, masiku ano zimadziwika kuti subtractive Production, mosiyana ndi njira zophatikizira zinthu zomwe zimayendetsedwa, zomwe zimadziwika kuti kupanga zowonjezera.

Ndendende zomwe gawo la "olamulira" limatanthawuza zimatha kusiyana, koma nthawi zambiri zimatanthawuza kugwiritsa ntchito zida zamakina (kuphatikiza ndi zida zamagetsi ndi zida zamanja). Imeneyi ndi njira yomwe imagwiritsidwa ntchito popanga zinthu zambiri zachitsulo, koma imatha kugwiritsidwanso ntchito pazinthu monga matabwa, pulasitiki, ceramic, ndi composites. The CNC Machining chimakwirira njira zosiyanasiyana monga mphero, kutembenuza, lathing, kubowola, honing, akupera ... etc.

| CNC Precision Machining Mphamvu | ||||

| Zothandizira | Kuchuluka | Size Range | Kukhoza Pachaka | Kulondola Kwambiri |

| Vertical Machining Center (VMC) | 48 seti | 1500mm × 1000mm × 800mm | 6000 matani kapena 300000 zidutswa | ± 0.005 |

| Horizontal Machining Center (VMC) | 12 seti | 1200mm × 800mm × 600mm | 2000 matani kapena 100000 zidutswa | ± 0.005 |

| Makina a CNC | 60 seti | Max kutembenukira dia. φ600 mm | 5000 matani kapena 600000 zidutswa | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) kapena GBT 6414 (China). | ||||

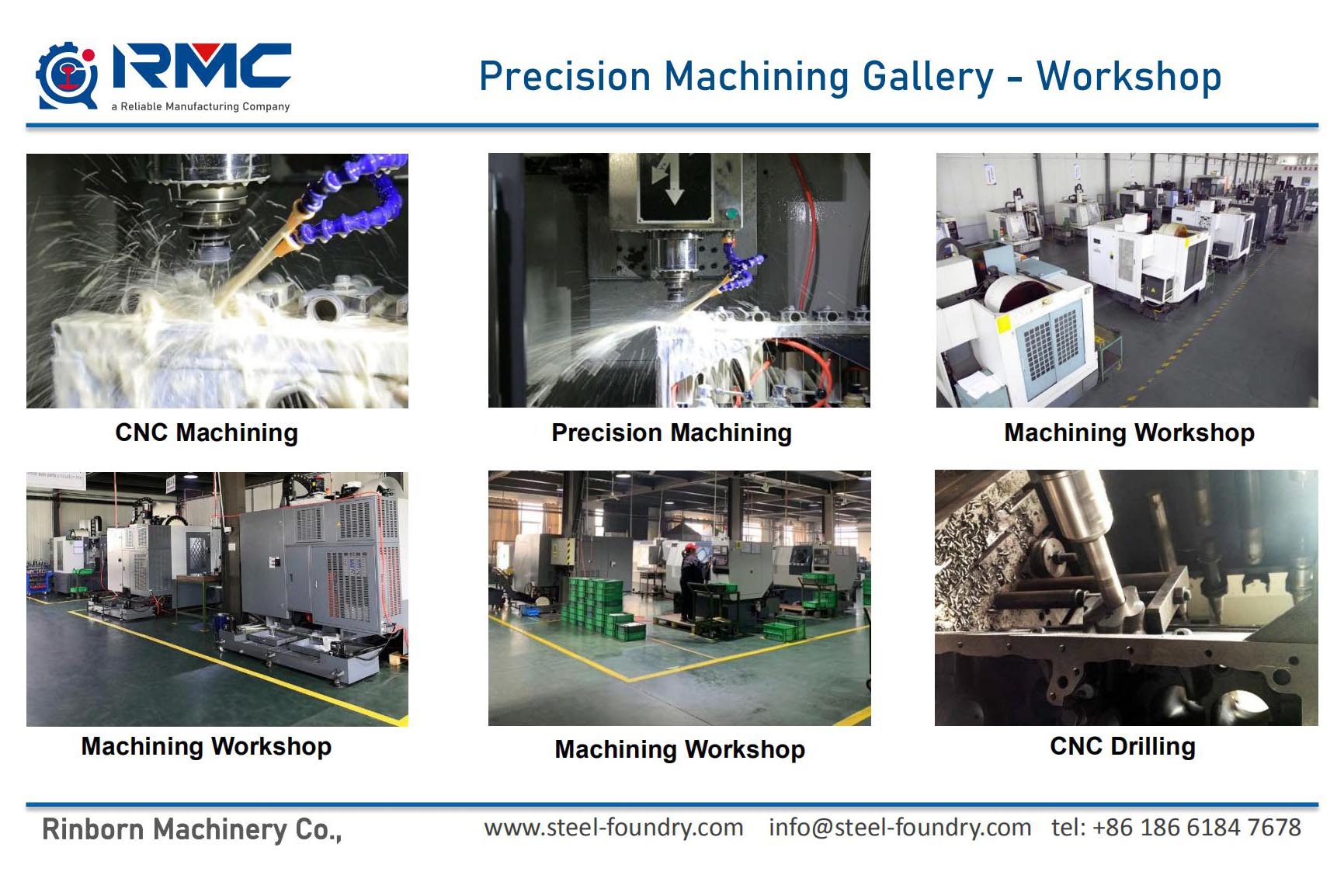

Malo opangira makina amapangidwa kuchokera ku makina a CNC mphero. Kusiyana kwakukulu kwa makina a CNC mphero ndikuti malo opangira makina amatha kusinthanitsa zida zopangira. Poika zida za zolinga zosiyanasiyana pa magazini ya chida, zida zopangira makina pa spindle zitha kusinthidwa ndi chosinthira chida chodziwikiratu mu clamping imodzi kuti muzindikire zida zambiri zamakina.

Malo opangira makina a CNC ndi chida chapamwamba kwambiri cha makina opangidwa ndi makina ndi makina a CNC ndipo ndi oyenera kukonza magawo ovuta. Malo opangira makina a CNC pano ndi amodzi mwa zida zamakina omwe amagwiritsidwa ntchito kwambiri padziko lonse lapansi a CNC omwe ali ndi luso lamphamvu lokwanira. Ikhoza kumaliza zambiri pokonza zinthu pambuyo poti workpiece ndi clamped nthawi imodzi. The processing kulondola ndi mkulu. Kwa ma batch workpieces omwe ali ndi vuto lapakati, mphamvu yake ndi nthawi 5-10 kuposa zida wamba, makamaka imatha kumaliza Zambiri zomwe sizitha kumalizidwa ndi zida wamba ndizoyenera kukonzedwa ndi chidutswa chimodzi chokhala ndi mawonekedwe ovuta komanso zofunikira kwambiri kapena kupanga magulu ang'onoang'ono ndi apakatikati amitundu ingapo. Imayang'ana ntchito za mphero, zotopetsa, kubowola, kugogoda ndi kudula ulusi pa chipangizo chimodzi, kuti zikhale ndi njira zosiyanasiyana zamakono.

Malo opangira makina amagawidwa m'malo opingasa komanso ofukula malinga ndi momwe alili panthawi yopanga ma spindle. Odziwika malinga ndi ntchito ndondomeko: wotopetsa ndi mphero Machining Center, pawiri Machining Center. Malinga ndi gulu lapadera la ntchito, pali: single workbench, pawiri workbench ndi Mipikisano workbench Machining Center. Malo opangira makina okhala ndi single-axis, dual-axis, three-axis, four-axis, five-axis and interchangeable headstocks, etc.

CNC Machining ndi mtundu wa makina olondola opangidwa ndi makina a CNC monga malo opangira makina apamwamba kwambiri omwe ali ndi mapeto apamwamba a 5 olamulira makina, 4 olamulira awiri a nsanja, kapena CNC kutembenuza lathes omwe angathenso kupangidwa kukhala CNC kutembenuza likulu kukhala ndi mphamvu yosintha zambiri. kuposa ocheka 15 mkati mwa kusinthana kumodzi; CNC mphero makina ndi CNC pobowola ndi pogogoda centers.Kulondola makina kuponya zitsulo ndi osiyana Machining mbiri zitsulo. Kuponyera mwatsatanetsatane kwakwaniritsa kale mawonekedwe enieni a zomwe mukufuna, motero kumapulumutsa makina ambiri poyerekeza ndi makina opangidwa ndi chitsulo mwachindunji. Komanso chifukwa cha ichi, nthawi zambiri timayenera kuganizira za machining pamwamba ndi chilolezo choyenera cha makina tisanaponye. Kugula kwathu nthawi zonse ndikujambula zojambula zosaphika pamodzi ndi zojambula zamakina kuti titchule malo opangira makina ndi chilolezo cha makina pazojambulazo.

RMC Investment casting foundry ili ndi malo opangira makina 4, ma seti 15 a CNC kutembenuza lathes ndi makina atatu a cnc mphero, pamodzi ndi wothandizira wamba wosinthasintha, mphero, kugogoda, kubowola ndi makina opera, tili ndi kuthekera kwa makina pafupifupi onse. mitundu ya castings zitsulo.

| Gulu Lofanana la Chitsulo cha Cast Alloy kuchokera ku Misika Yosiyana | |||||||||

| MABUKU | AISI | W-otsika | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Chitsulo cha Low Alloy | 9255 | 1.0904 | 55 ndi7 | 250 ndi 53 | 2090 | 55 ms7 | 56 ndi7 | - | 5 SS8 |

| 1335 | 1.1167 | 36 mn5 | 150 M36 | 2120 | 40 m5 | 36 mn5 | SMn 438(H) | - | |

| 1330 | 1.1170 | 28 mn6 | 150 M28 | - | 20 m5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Kr6 | 534 ndi 99 | 2258 | 100c6 pa | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 mz3 | 1501 240 | 2912 | 15d 3 | 16 mo3 | Mtengo wa STBA12 | 16 Mo3 kW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 m20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311 Mtundu 7 | - | 40 NCD 2 | F.129 | Chithunzi cha SNCM240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 ndi 16 | - | 18 NCC6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 mkh4 | 530 ndi 32 | - | 32c4 ndi | 35Kr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 mkh4 | 530 ndi 40 | - | 42c2 ndi | 42 mkh4 | SCr 440 (H) | 40Kr4 | |

| 5140 | 1.7035 | 41 mkh4 | 530 ndi 40 | - | 42c2 ndi | 42 mkh4 | SCr 440 (H) | Mtengo wa 41Cr4 KB | |

| 5140 | 1.7045 | 42 mkh4 | 530 ndi 40 | 2245 | Mtengo wa 42C4TS | F.1207 | Mtengo wa 440 | - | |

| 5115 | 1.7131 | 16 mcr5 | (527 M 20) | 2511 | 16 mc5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 mkh3 | 527 ndi 60 | 2253 | 55c3 ndi | - | MFUNDO 9 (A) | 55kr3 | |

| 4130 | 1.7218 | 25 Crmo4 | Chithunzi cha 1717CDS110 | 2225 | 25 cd4 pa | F.1251/55Cr3 | SCM 420/SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 Krmo 4 | 708 ndi 37 | 2234 | 35 cd4 pa | 34 CrMo 4 | Mtengo wa SCM432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 Crmo 4 | 708 m40 | 2244 | Chithunzi cha 42CD4TS | 42 Crmo 4 | Mtengo wa SCM440 | 41 Crmo 4 | |

| 4140 | 1.7225 | 42 Crmo 4 | 708 m40 | 2244 | pa cd40 | F.1252 | Mtengo wa SCM440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 Crmo 4 | 708 m40 | 2244 | 42 cd4 pa | F.1252 | Mtengo wa SCM440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 KrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | Mtengo wa 12CrMo910 | |

| - | 1.7361 | Mtengo wa 32CrMo12 | 722 m24 | 2240 | 30 cd 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 Crv4 | 735 ndi 50 | 2230 | 50 CV4 | F.143 | PA 10 | 50CrV4 | |

| - | 1.8515 | 31 KrMo 12 | 722 m24 | 2240 | 30 cd 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Chitsulo cha Aloyi Chapakati | W1 | 1.1545 | C105W1 | BW1A | 1880 | ndi y105 | F.5118 | SK 3 pa | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL3 ndi | (2140) | ndi 100C6 | F.520 L | - | - | |

| L2 | 1.2210 | Chithunzi cha 115KV3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | Chithunzi cha 105WC6 | - | 2140 | 105W C 13 | F.5233 | Chithunzi cha SKS31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCRV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 m40 | 2541 | 35 NCD 6 | F.1280 | Chithunzi cha SNCM447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr5 | - | - | 20 mc5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Chida ndi High Alloy Steel | D3 | 1.2080 | Chithunzi cha X210KR12 | BD3 ndi | 2710 | Z200 C12 | F.5212 | Chithunzi cha SKD1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | Mtengo wa 40CM8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Chithunzi cha Z40CDV5 | F.5318 | Chithunzi cha SKD61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z100 CDV 5 | F.5227 | Chithunzi cha SKD12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Chithunzi cha Z160 CDV12 | F.520.A | Chithunzi cha SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | Chithunzi cha X210 CrW 12 | BD6 | 2312 | Chithunzi cha Z200CD12 | F.5213 | Chithunzi cha SKD2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCRV9 3 | BH21 ndi | - | Zithunzi za 30WCV9 | F.526 | SKD5 | X30WCRV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | Chithunzi cha 55 NCDV7 | F.520.S | Chithunzi cha SKT4 | - | |

| m 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SHKH 55 | HS6-5-5 | |

| M2 | 1.3343 | S6/5/2 | BM2 | 2722 | Chithunzi cha Z85WDCV | F.5603 | SHKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 92 | - | - | HS2-9-2 | |

| pa HW3 | 1.4718 | X45CrSi 9 3 | 401 ndi 45 | - | ndi 45 CS9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 mcr4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Chitsulo Champhamvu Champhamvu Kwambiri | A128 (A) | 1.3401 | Chithunzi cha G-X120MN12 | BW10 | 2183 | Z120 M12 | F.8251 | Chithunzi cha SCMnH1 | GX120Mn12 |

Maluso aInvestment Casting Foundry:

• Kukula Kwambiri: 1,000 mm × 800 mm × 500 mm

• Kulemera kwake: 0,5 kg - 100 kg

• Mphamvu Zapachaka: matani 2,000

• Zida Zomangamanga Zomanga Zipolopolo: Silica Sol, Madzi Glass ndi zosakaniza zake.

• Kulekerera: Popempha.

Ubwino waInvestment Casting Components:

- Kumaliza kwabwino komanso kosalala pamwamba

- Kupirira kolimba kwambiri.

- Mawonekedwe ovuta komanso otsogola okhala ndi kusinthasintha kwamapangidwe

- Kutha kuponya makoma owonda motero gawo lopepuka loponyera

- Kusankhidwa kwakukulu kwazitsulo ndi ma aloyi (zachitsulo komanso zopanda chitsulo)

- Kukonzekera sikofunikira pakupanga nkhungu.

- Kuchepetsa kufunika kwa makina achiwiri.

- Kuwonongeka kwazinthu zochepa.

| Zida Zopangira Investment ndiCNC Machiningku RMC Foundry | |||

| Gulu | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Chitsulo chosapanga dzimbiri cha Austenitic | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Mvula Kuumitsa Zitsulo Zosapanga dzimbiri | Mtengo wa 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Chitsulo chosapanga dzimbiri cha Duplex | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Chida Chitsulo | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Chitsulo Chosagwira Kutentha | 20Cr25Ni20, 16Cr23Ni13, Mtengo wa 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminiyamu Aloyi | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Giredi 31 | 2.4778 | |

Zomwe zimatchedwanso makina olondola, makina a CNC amatha kufika pakulondola kwambiri pakulolerana kwa geometical ndi kulolerana kwapang'onopang'ono. Ndi makina athu a CNC ndi Horizontal Machining Centers (HMC) ndi Vertical Machining Centers (VMC), titha pafupifupi kukwaniritsa magiredi anu onse ofunikira.

| KULAMBIRA KWA Investment CASTING TOLERANCES | |||

| mainchesi | Mamilimita | ||

| Dimension | Kulekerera | Dimension | Kulekerera |

| Mpaka 0,500 | ±.004" | Mpaka 12.0 | ± 0.10mm |

| 0.500 mpaka 1.000" | ±.006" | 12.0 mpaka 25.0 | ± 0.15mm |

| 1.000 mpaka 1.500 " | ±.008" | 25.0 mpaka 37.0 | ± 0.20mm |

| 1.500 mpaka 2.000" | ±.010" | 37.0 mpaka 50.0 | ± 0.25mm |

| 2.000 mpaka 2.500" | ±.012" | 50.0 mpaka 62.0 | ± 0.30mm |

| 2.500 mpaka 3.500" | ±.014" | 62.0 mpaka 87.0 | ± 0.35mm |

| 3.500 mpaka 5.000" | ±.017" | 87.0 mpaka 125.0 | ± 0.40mm |

| 5.000 mpaka 7.500 " | ±.020" | 125.0 mpaka 190.0 | ± 0.50mm |

| 7.500 mpaka 10.000" | ±.022" | 190.0 mpaka 250.0 | ± 0.57mm |

| 10,000 mpaka 12.500 " | ±.025" | 250.0 mpaka 312.0 | ± 0.60mm |

| 12.500 mpaka 15,000 | ±.028" | 312.0 mpaka 375.0 | ± 0.70mm |